With the help of Simon Process Engineering GmbH from Neu-Bamberg and under the direction of Prof. Dr tech. Ralf Simon, a regenerative energy concept has been developed that will enable WDS to produce 60% of the energy it requires in the form of electricity and gas, at least in the summer months. For this purpose, 26 heat pumps with a total of 8 buffer tanks and 1500 solar modules with a total output of 570 KWp were installed on the roofs. In addition, 10 electromobility charging stations will be used in the future so that the company’s employees will also have a convenient means to charge their steadily growing fleet of private electric cars during working hours.

Ensuring an ecologically sustainable energy supply is important for private households and businesses alike. Manufacturing companies in particular play an important role in the energy turnaround, as they consume a lot of energy and, as commercial enterprises, must fulfil their social responsibility within their region and beyond.

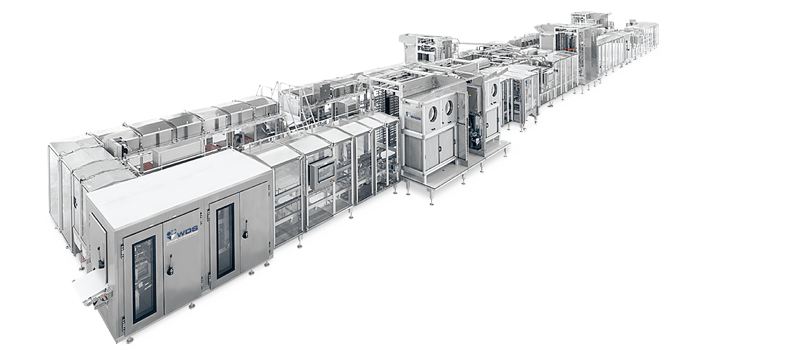

For this reason, the Rengsdorf-based company Winkler und Dünnebier Süßwarenmaschinen GmbH has been continuously involved in the creation of a regenerative energy concept over the past few years. Even prior to current developments, WDS has taken sustainable heat production into account by investing in extensive photovoltaic systems and in the construction of new buildings, among other measures. In the wake of an increasing awareness of this issue and geopolitical changes in the energy sector, the company has intensified its investments once again in recent months.

The installation and commissioning phases for all planned measures will be completed in the summer of 2023.

In addition to major investments, the constant monitoring and further development of existing resources also represent an important contribution to the conservation and sensible use of energy. At WDS, for example, the heat generated by laser systems or compressors in production is used during the heating season in order to reduce the reliance on the heating systems in the production halls. Existing heating systems are being continuously optimised, while state-of-the-art sensor systems provide data on heat levels in the office and production areas, thereby supporting the temperature control of the buildings.

In total, WDS has invested €1.5 million in improving its own carbon footprint, taking an important step towards avoiding fossil fuels to achieve greater sustainability. Managing Director Jessica Runkel and Energy Officer Andreas Forst see these measures as an important first step and intend to implement further measures together with Professor Simon. The goal is to equip all available roofs and potentially the parking areas with PV systems so that the company can generate 100% of its required energy itself, at least in the summer months.

Deutsch

Deutsch  English

English  Русский

Русский