The new high speed setting solution

for gelatine gummy production

GELITA, Hänsel and WDS combine their expertise to revolutionize gelatine gummy production: Reusable silicone moulds replace traditional starch trays. Our innovative solution creates significant added value for our customers.

Produce starch-free

- Realize starch-free gummies and OTC-products

- Reduce material handling to a fraction against the classic process

- Avoid dust, residues or cross-contamination caused by the use of starch

Reduce production time

- Produce within one hour instead of two days

- Forget about drying and long cooling procedures

Minimize production cost

- Replace ten thousands of starch trays by some hundreds of reusable silicone moulds

- Save production space

- Save energy and manpower

Simplify fortification

- Fortify gummies by gentle treatment of ingredients

- Process collagen peptides, vitamins, minerals, APIs etc. easily

-

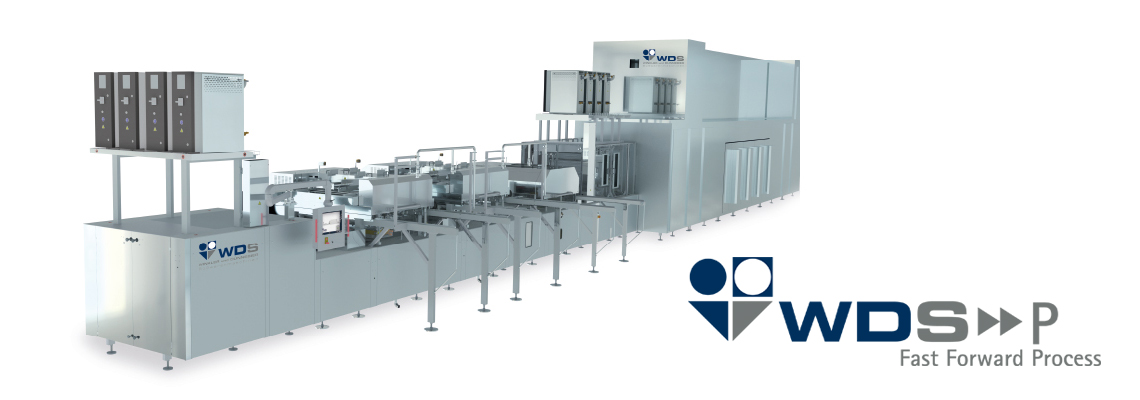

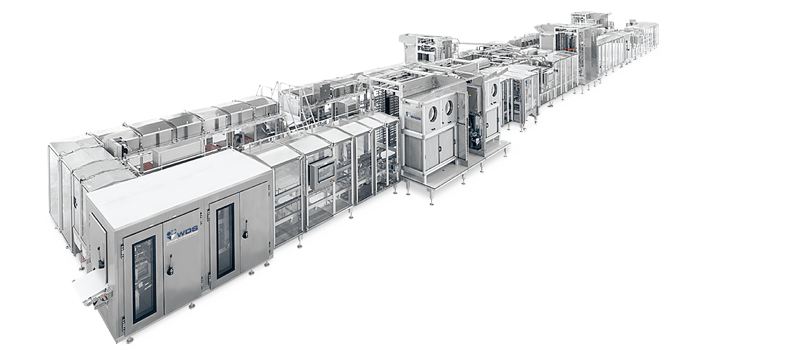

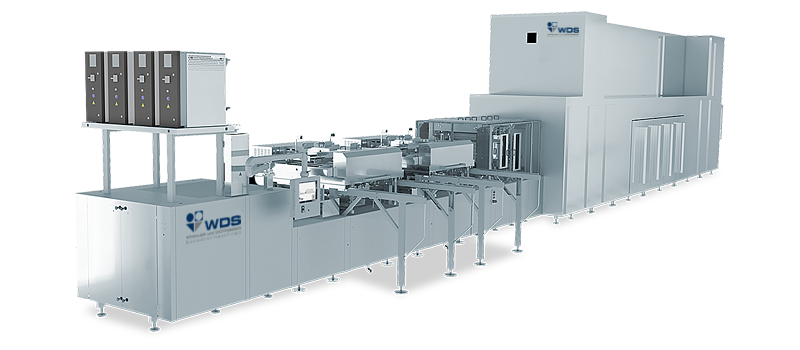

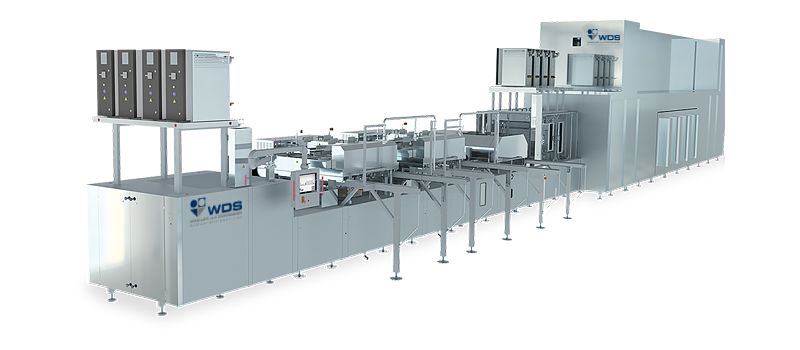

The new depositing line

WDS globally known for its diversity in confectionery depositing has applied their longterm expertise in starchless moulding.

The result is a modern depositing line tailored to the needs of the >>P technology enabling depositing and de-moulding of the products along with other process steps such as oiling or sanding the products.

-

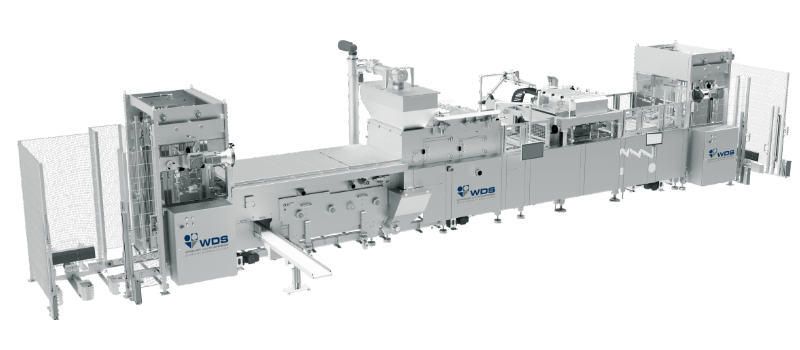

The new cooking process

Hänsel Processing GmbH, with more than 100 years of experience in the market, is one of the leading companies for sugar confectionery processing lines.

Customers’ and our own ideas about confectionery production are brought into life in the technological CandyLab. R & D results are always integrated into new or advanced machines, installations and procedures and definitely contribute to ensure the economic success of the customer on their respective markets.

-

The new formulation

As global leader in gelatine and collagen protein production, GELITA developed an innovative formulation to enable fast setting and immediate de-molding in starch-free gelatine gummy production.

Deutsch

Deutsch  English

English  Русский

Русский