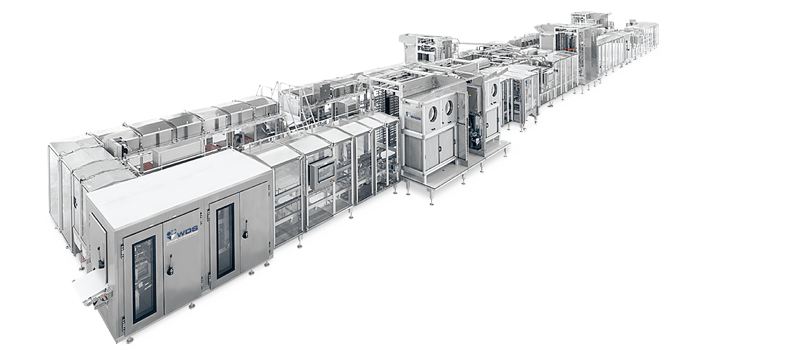

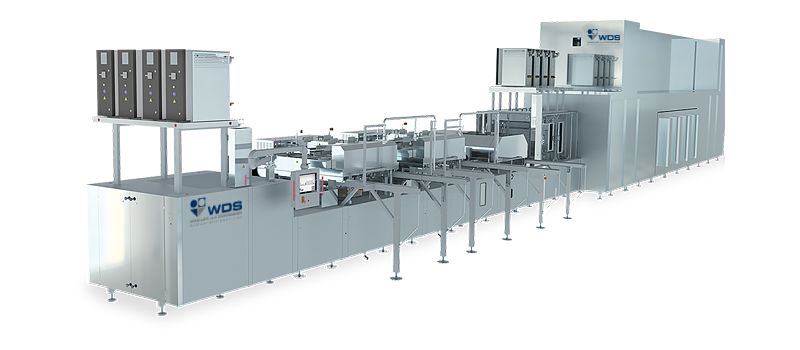

Create a diverse range of chocolate or jelly confectionery products with just one production line – with or without filling!

The innovative ConfecVARIO machine concept ensures efficient and highly economical production of your confectionery products. The modular design ensures a high degree of scalability of the plant. The modular design minimises production faults or downtimes due to plant shutdowns, as parts of the plant can continue to produce if worst comes to worst.

Most of the maintenance and cleaning of the plant can also be carried out during operation – for example, maintenance and cleaning sections can be integrated, in which the mould carriers can wait. This means that individual sections of a plant can be shut down and serviced without interfering with ongoing production.

Chocolate

The innovative machine concept of ConfecVARIO makes it possible to produce a wide variety of chocolate articles. Produce filled or solid chocolates with and without additives on the chainless plant. The highly flexible production line enables precision depositing, EasyClean designs and absolute flexibility.

Gum & Jelly

With ConfecVARIO, you can produce a wide variety of gum and jelly products. Produce hygienically in polycarbonate moulds, dose with the highest possible depositing accuracy, and shape the products in a gentle and organised manner.

sweetOTC

Succeed in the market for dietary supplements and over-the-counter medicines with trendy, tasty and active effective OTC confectionery.

ConfecVARIO is a plant for the production of OTC confectionery, taking into account all relevant hygienic aspects. It can also be customised specifically to meet your requirements.

-

Highlights

- Wide variety of chocolate and/or jelly products

- Flexible plant layouts thanks to modular design

- Maintenance and cleaning during operation

- Innovative transport system takes over additional functions such as lifting, vibration or ribbon depositing movements

- Chainless mould conveyor for maximum hygiene and cycle independence

- VarioCABINET: Individual shelves in the cooling cabinet that can be removed without tools

- Optimum accessibility

- Unrestricted process observation

- Very short changeover times

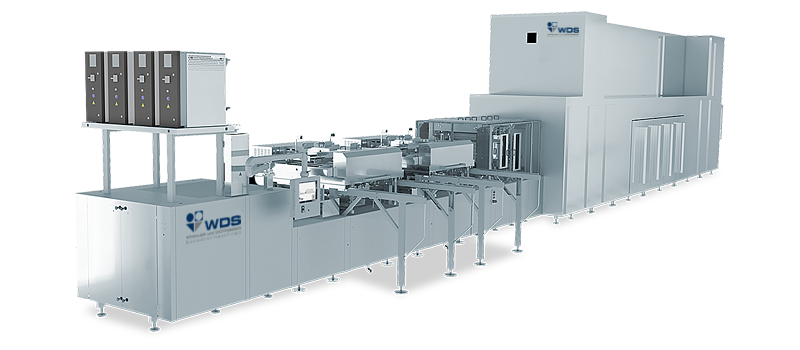

Multifunctional.

Variable dwell times for cooling, warming, holding and buffering of products.

Highlights

Set-up:

- The moulds are loaded and unloaded from a rotating rack system by gantry kinematics

- Chainless design

Process:

- Freely selectable dwell times

- Optimised airflow thanks to modern airflow simulation

- Constant, reproducible cooling results on all levels

Cleaning:

- Easy accessibility to all areas of the VarioCABINET

- Shelves can be removed from the VarioCABINET without tools

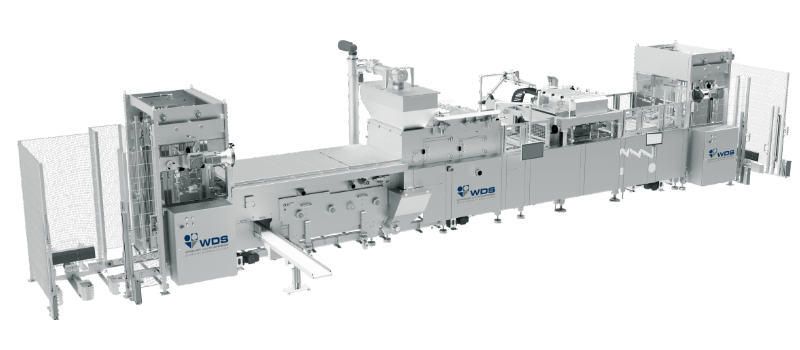

High-precision pouring.

Mould carrier with lifting function & newly defined vibration function

Merging of the depositing process and the vibration function with an innovative mould carrier.

Highlights

- Vibrate during depositing

- Horizontal, vertical and combined vibration immediately after depositing without loss of time

- Precise ribbon deposit thanks to millimetre-accurate movement of the mould carrier

- Multiple depositing in rows with lifting function

- Combinable lift and vibration function

Innovative

mould conveyor

VarioTRACK enables different speeds within a single plant. The mould carriers can be moved and positioned individually with millimetre precision.

Highlights

- Chainless, precise mould conveyor

- Transport with variable speed sections

- New plant layouts possible with switch systems

![]()

LISTENING

![]()

UNDERSTANDING

![]()

COMMON PATH

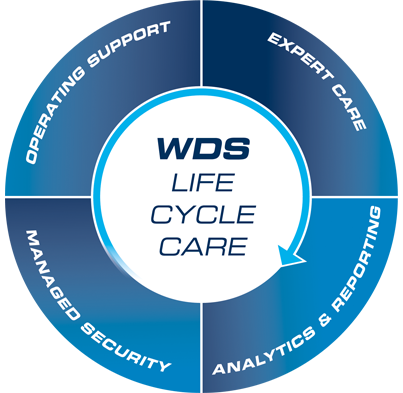

Listening to You!

Listening, understanding and finding the best paths – that's our strength!

Starting with your product idea, we develop the suitable plant concept for a ConfecVARIO in close cooperation with you. In the process, we address your individual needs and adapt the plant together with you.

Diverse product options. Implementing new ideas easily

A wide range of chocolate and jelly products with just one plant type.

Highlights

- Produce different chocolate & jelly products in parallel or alternately

- Chainless version for fast cleaning between product types

- Short changeover times by bypassing plant parts not used

Different speeds

during ongoing production

The slowest process does not affect the overall plant speed.

Highlights

- Different speed ranges for optimum processing of part functions

- Conveyor can be switched over from intermittent to continuous within millimetres

- Short set-up and cleaning times

- Increased plant output by having processes run in parallel

Modularity. Flexibility. Diversity.

Completely new plant layouts and flexibility in the diversity of process steps and their arrangement.

Highlights

- New plant layouts thanks to track switch system as well as 90° and 180° curves

- Modular extendibility for the fast, later addition of process steps such as chocolate shell edge formation

- Lift/lower function and mould vibration can be switched on by software anywhere in the plant

Variable output quantities.

Tailored individually

Flexible production processes for medium to high capacities possible on the same plant.

Highlights

- Different mould circuits can be combined flexibly

- Plant parts only required for one special product are run through, which saves on cleaning

- Specific adaptation of the number of moulds to a product since free sections are travelled over more quickly

Diverse plant layouts

Compared to chain-driven plants, ConfecVARIO makes it possible to have a variety of plant layouts and is extremely space-saving at the same time. The innovative transport system can take over additional functions, such as ribbon depositing movements, lifting functions or vertical and horizontal vibration movements. Processes can be performed completely asynchronously: The transport of the mould carriers is no longer dependent on a workstation.

Deutsch

Deutsch  English

English  Русский

Русский