Perfect accessibility and highest hygienic level

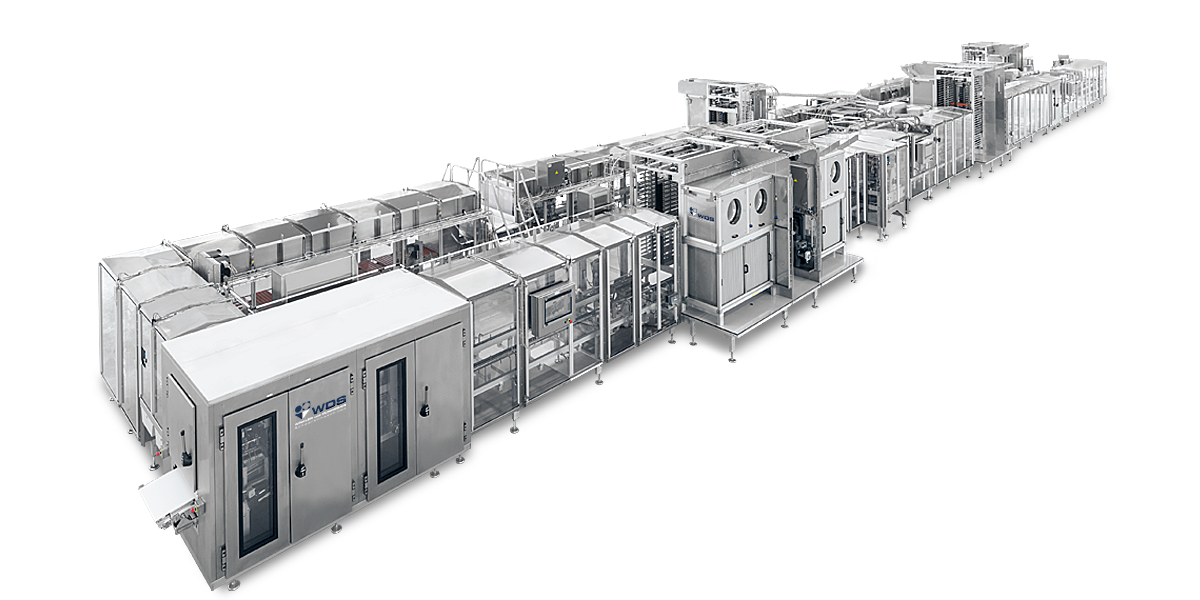

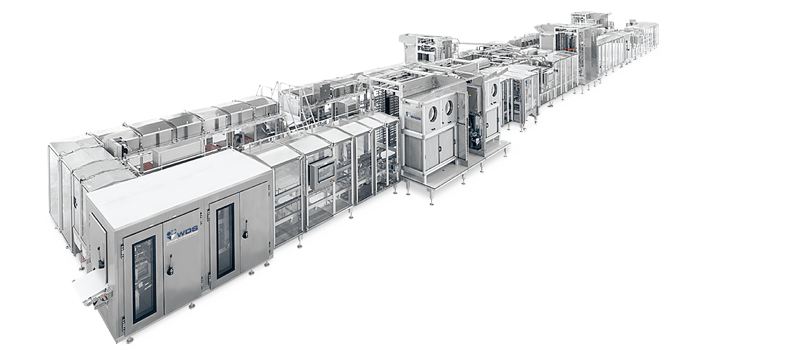

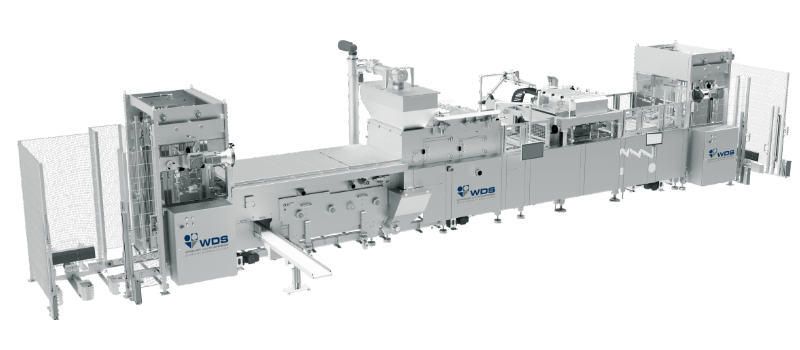

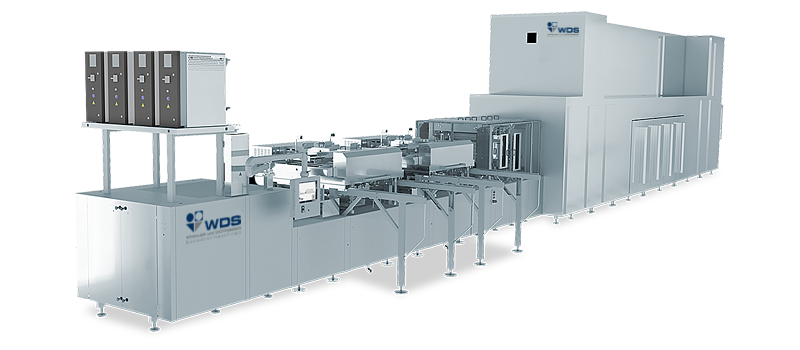

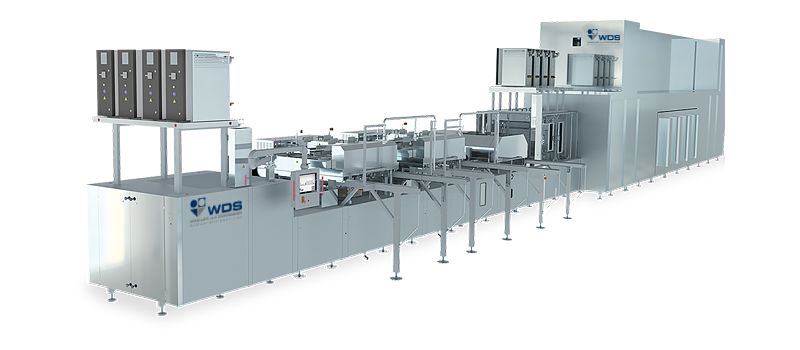

The WDS moulding plant ConfecPRO is designed for depositing medium to high capacities of filled and solid chocolates. The modular, highly flexible production line can be designed for one or two lanes, at ground level or over several floors.

Thought out to the last detail

Due to the modular design of the WDS ConfecPRO, an adaptation or extension of the plant based on changing customer requirements is possible at any time. The decentralized control concept allows adding stations, especially when free spaces are planned. Through this flexibility and the large number of available aggregates, the widest possible product range can be realized.

Chocolate

Launch a new dimension in chocolate production with the ConfecPRO. With the moulding plant, you can produce filled or solid chocolates with or without additives. The highly flexible production line offers maximum moulding accuracy, EasyClean designs and short changeover times for the confectionery production of tomorrow.

Gum & Jelly

Take your jelly production to a new level with ConfecPRO for the production of filled and solid products made of gum and jelly. Produce hygienically in polycarbonate moulds, dose with the highest possible depositing accuracy, and shape the products in a gentle and organised manner.

sweetOTC

Succeed in the market for dietary supplements and over-the-counter medicines with trendy, tasty and active effective OTC confectionery.

ConfecPRO is a plant for the production of OTC confectionery, taking into account all relevant hygienic aspects. It can also be customised specifically to meet your requirements.

-

Characteristics

- Almost unrestricted process monitoring and

optimum accessibility for cleaning thanks to

large panel doors and open frame design - Maximum depositing accuracy due to precise

in-house manufacturing and wear-resistant

materials - Short set-up times for mass changes thanks

to tool-free quick change of almost all plant

parts in contact with mass (EasyClean) - Compliance with the highest hygiene standards

- Fast on-site installation and easy expansion

through decentralized control principle and

modular components - Floor clearance of at least 350 mm

- Wide variety of products and technologies:

- Pralines, bars or tablets with or without

ingredients - Solid or filled products

- Multi-shot, cold stamping,

- Pralines, bars or tablets with or without

- Almost unrestricted process monitoring and

-

Technical Data

- Mould size 425 – 860 mm x 275 – 450 mm

- Plant speed up to 25 moulds/min

- Output up to 5 t/h (depending on product, mould size and speed)

- Working height 1.000 mm

ConfecPRO Highlights

Touch panel

Intuitive operation and recipe memory.

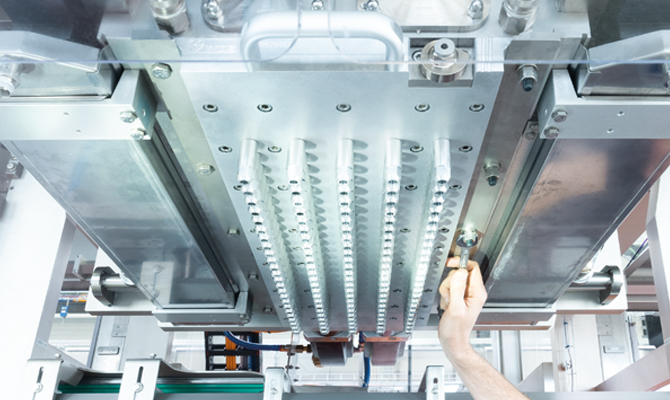

Depositing tool

Easy change of nozzle bar.

Cooling station

Upward and Downward sections (2 zones).

Transport

Optimal access.

Depositor

Extractable.

Scraper

Tool-free change of the mass-contacting parts.

Deutsch

Deutsch  English

English  Русский

Русский