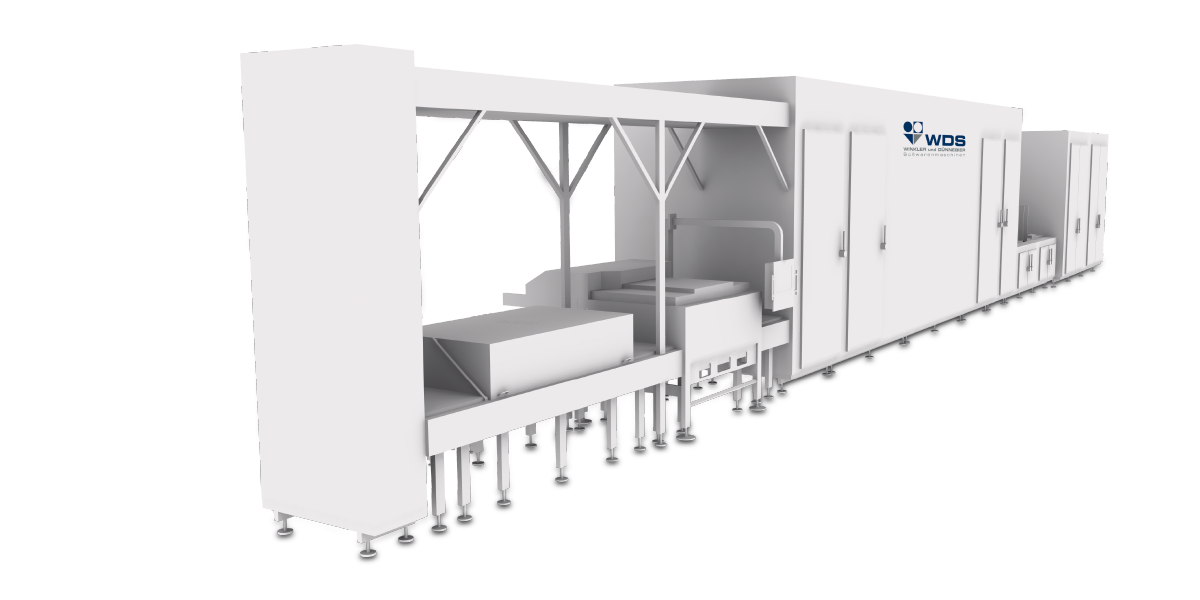

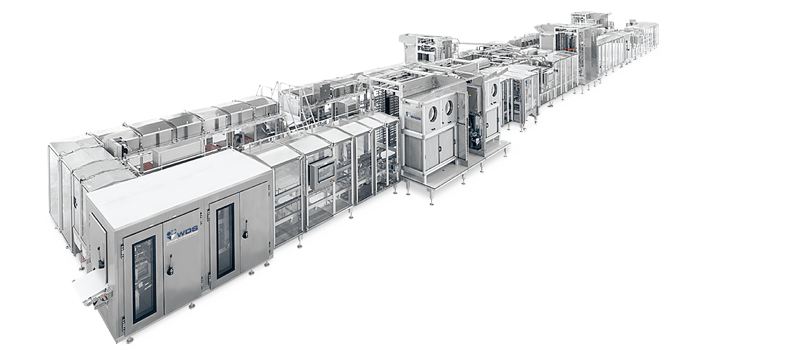

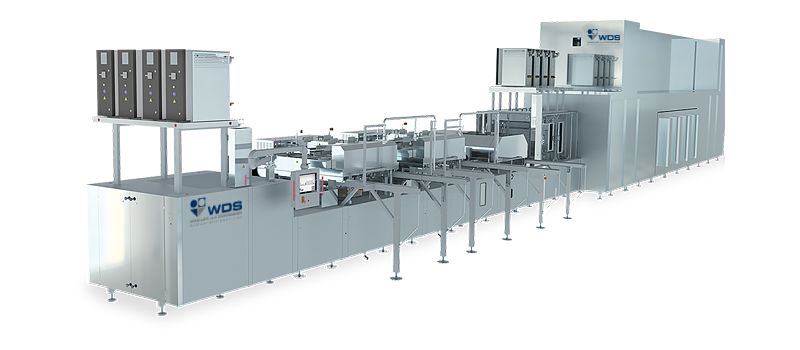

The WDS Moulding plant type 273 is designed for the production of solid chocolate products with or without ingredients and filled products by means of One-Shot- as well as Triple-Shot technology.

-

Characteristics

- Modularly designed manufacturing plant

- One lane endless chain plant with continuously running chain

- "Loose-mould" system with the well-proven mould carriers

- The special design of the chain return ensures that the moulds are always placed horizontally

- Synchronous drive of all plant elements by servo motors with torque control

- Hygienic plant design, easy to operate and to service

-

Technical Data

- Plant speed up to 70 moulds / minute

- Mould size of 892 x 220 mm up to 1172 x 420 mm

- Output up to 18 t/h (depends on product, mould size and speed)

Stations

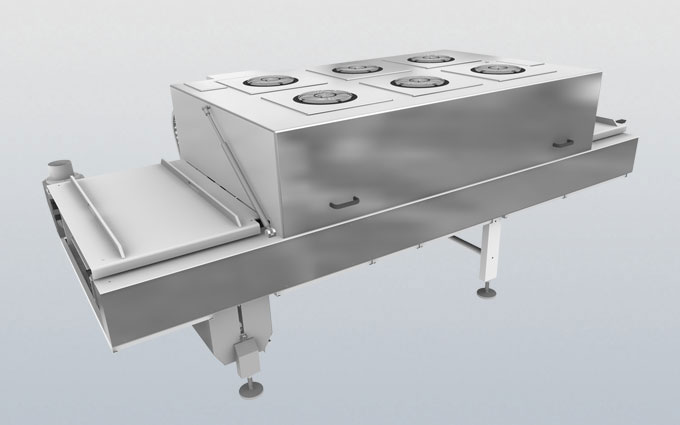

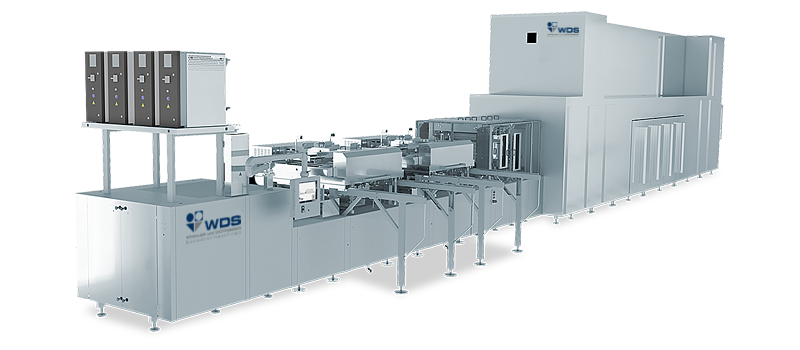

Heating section

- Mould heating by IR radiators

- Automatic shutdown in case of plant stoppage

- Venting by fans

- No overheating of moulds

- Alternative: heating by heating cabinet

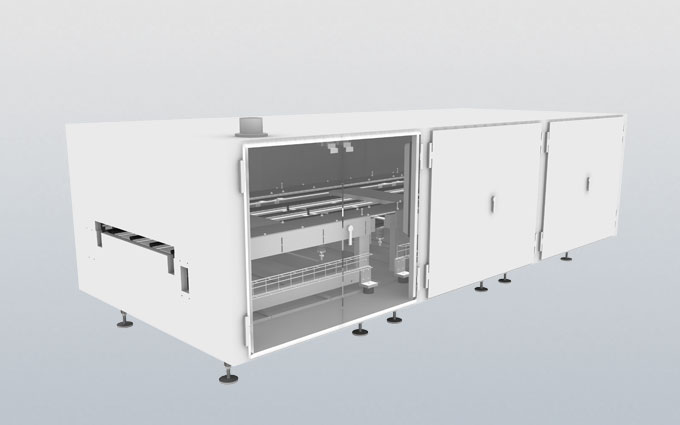

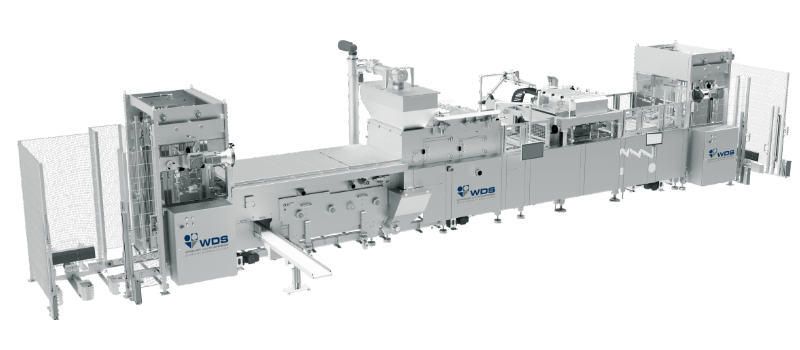

Depositor

Depositors with servo-electrical drives in various designs according to customer requirements.

- Mono-, One-Shot or Triple-Shot execution

- Rotary valve or slide valve depositors

- Depositors with separated pump systems

- Depositors with thermally insulated pump systems

- Extractable depositors

- Depositors in “EasyClean” execution

Vibration station

- combined vertical and horizontal mould vibration

- Customer-optimized execution

- Space-saving designed cooling cabinet

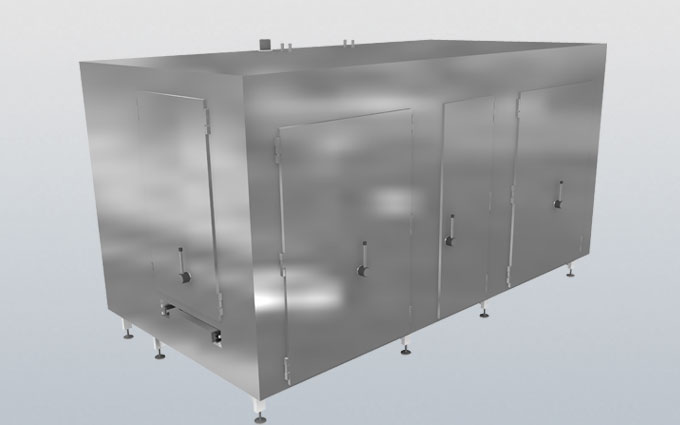

Cooling cabinet

- Endless chain cooling cabinet

- “Loose-mould”-endless chain with well-proven mould carriers

- Mould is always aligned horizontally

Demoulding station

- Automatic product demoulding

- Product specific adjustable demoulding hammers

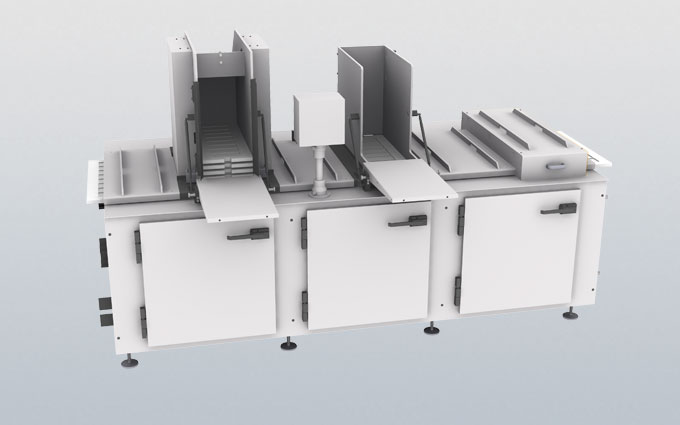

Mould exchanger incl. empty mould detector

- Mechanical or optical empty mould control

- Automatic mould discharge and infeed

- Semi-automatic mould set exchange

Deutsch

Deutsch  English

English  Русский

Русский