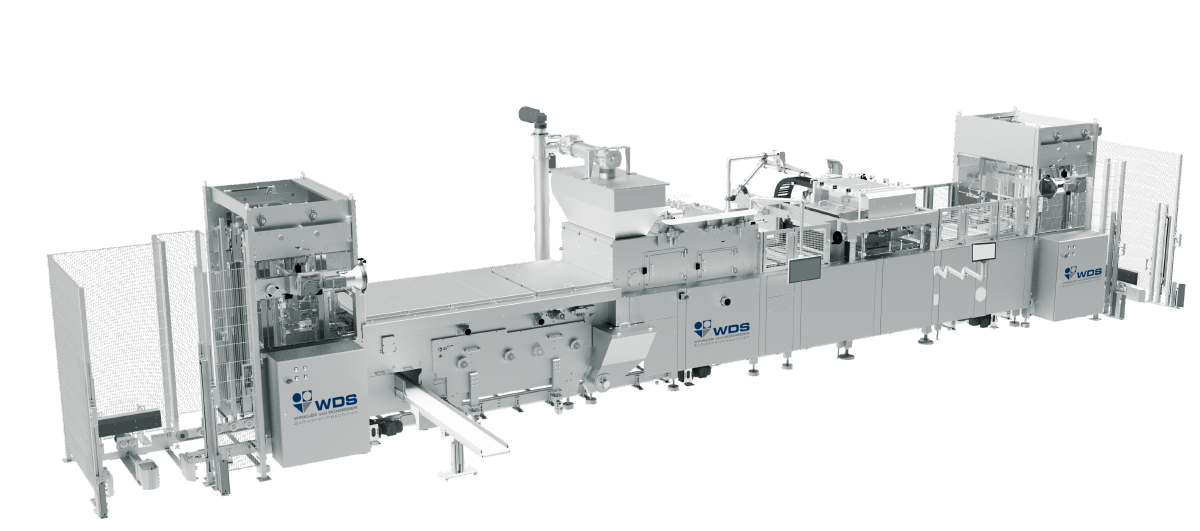

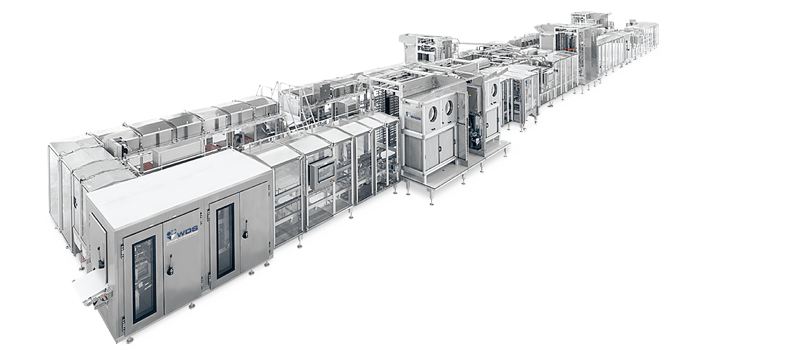

The Mogul Plant type 660 is designed for the manufacture of all starch-moulded products, such as gum and jelly (on pectin, gum arabic, gelatine, agar-agar or carrageenan basis) as well as liquorice, fondant, cream, marshmallow foam and similar items. Furthermore the equipment is suitable for depositing liqueur. The large variety of depositing systems, full-tray technology, Mono, One-Shot, Starlight with filling etc. allows various depositing processes.

Characteristics

-

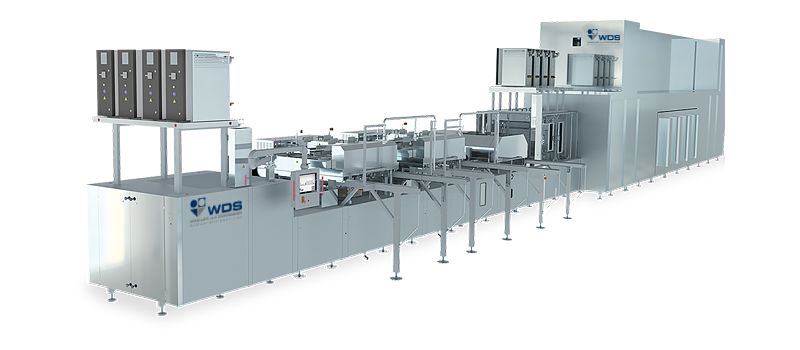

Transport

- Perfect tray guiding through chainless WDS-GuidedPusherSystem

- Continuous tray transport from tray feeder to stacker without transition points

- Lacquer-free plant by using stainless steel and stainless materials

- Low maintenance, i.e. thanks to programmable single servo-electrical drives

- Quick installation and possibilites of enlargement by decentral automation

-

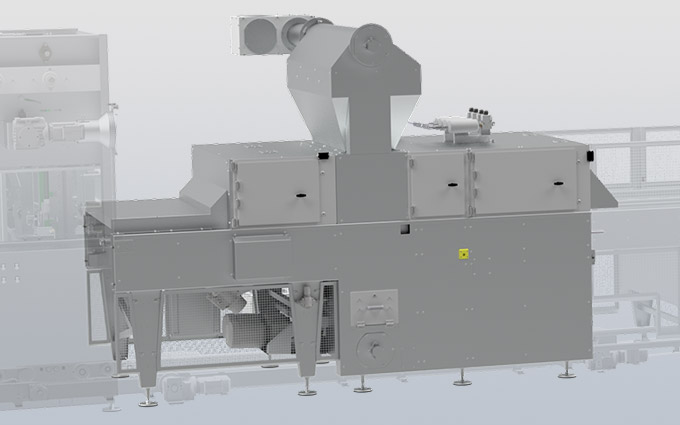

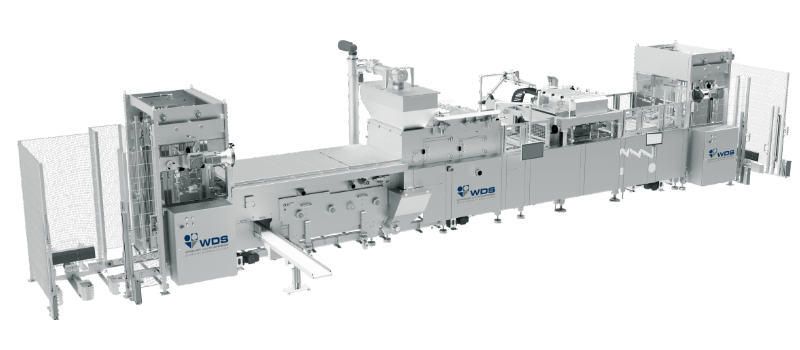

Depowdering/Stamping

- Excellent precleaning section thanks to air knife

- Modular design of the drum with practical sieving segments allows easiest cleaning and maintenance

- Screen baskets made of stainless steel

- Circumferential brushless tray edge cleaning with air knife and suction table (WDS-patent)

- Servo-driven stamping head with product-specific stamping curve for high stamping quality

- Quick, tool-free exchange of stamping board

-

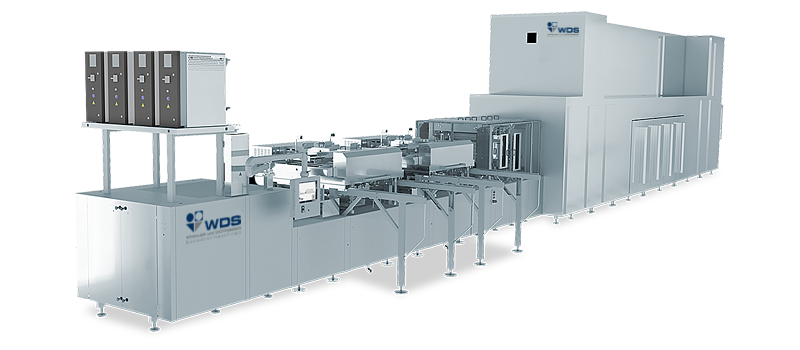

Depositing

- Large variety of depositing processes in basic plant layout (Mono, Centre-in-Shell and Starlight with filling)

- Custom-specific Moulding lines, e.g. temperature separation between shell and filling depositor

- Precise colour separation (one rotary valve for only one colour)

- Tool-free exchange of program plates

- Optional, lateral extractability of the whole depositing head for easy pumping off of mass and for cleaning next to the main transport

-

Technical Data

- Mechanic plant speed up to 35 trays per min.

- Up to 8 colours/flavours per depositor

- Pump system depending on product dataFull-tray system up to 22 x 38 pistons

- Tray dimensions 360-440 x 760-840 mm

- Starch tray stacking height up to 3200 mm

- Pallets for 2 or 3 stacks

- Working height 1340 mm / 1370 mm

Stations

Pallet conveyor tray feeding for pick-up and transfer of pallets

- Available in two versions: normal or heavy-load design

- Buffer spaces available for pallets before feeder

- Available in three designs: straight, lateral feeding or turntable

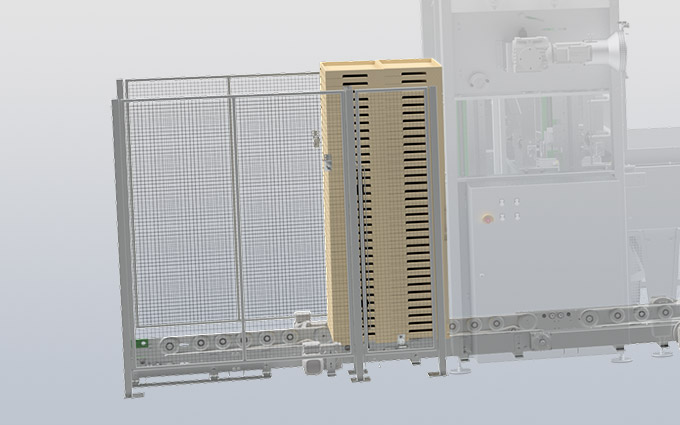

Feeder for separation of tray stacks

- Available in different installation heights

- Number of trays per partial stack adjustable upon customer's request

- Tray separation by partial stacking unit

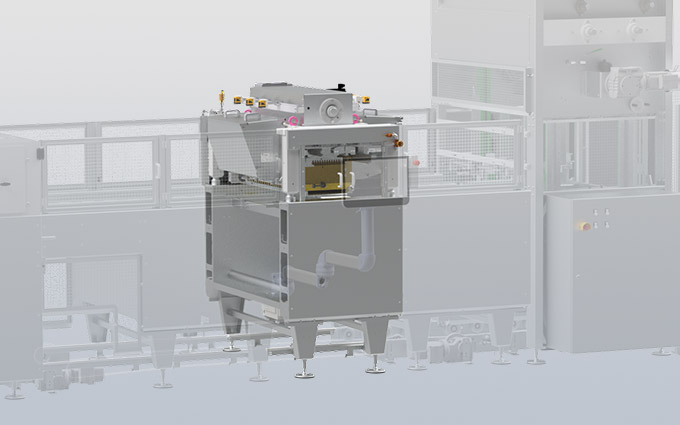

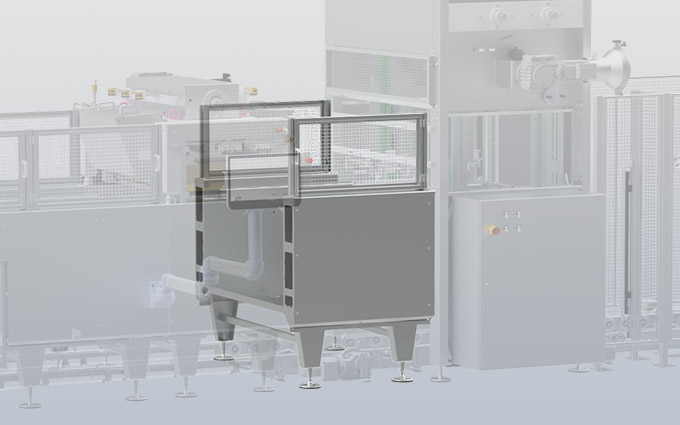

Starch buck for emptying, filling and stamping of trays

- Tray turning unit, turning by 360° in two work cycles

- Connection to starch conditioning unit

- Customer specific starch circuit, e.g. with cyclone screener

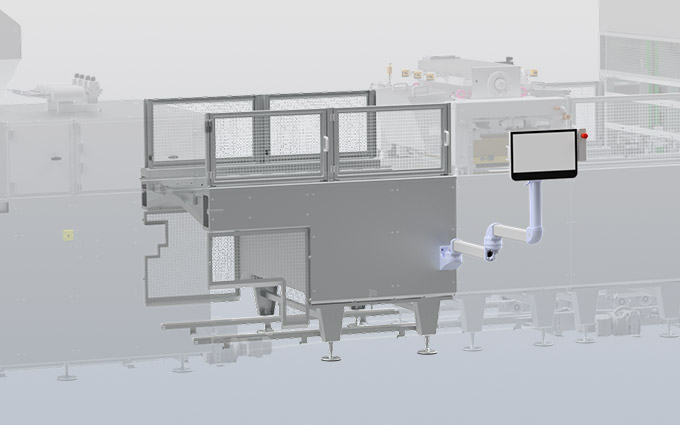

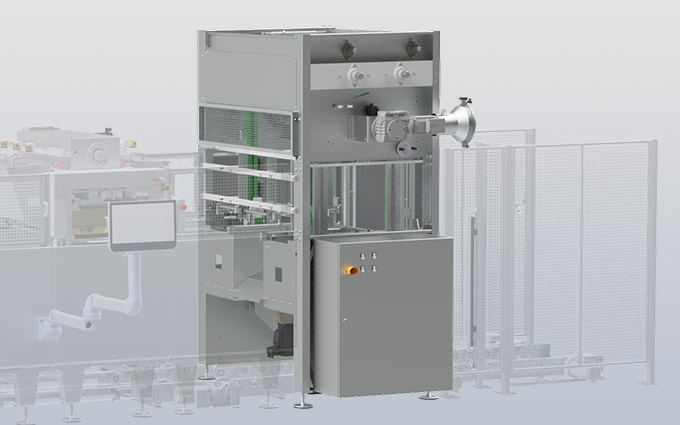

Drive unit for transport of starch trays

- Central drive of WDS-GuidedPusherSystem

- Control of stamping quality for reducing spoiled depositing by irregular depositing processes

- Sheet loading device for checking of depositing weights

Depositor for highly-precise depositing of different Mogul masses

- No unintentional colour mixing

- Mono-, One-Shot technology as well as Starlight with filling possible

- Easy exchange of product-dependent programme parts

Space for enlargements

- Starch sprinkler

- Lifting device for removal of starch trays

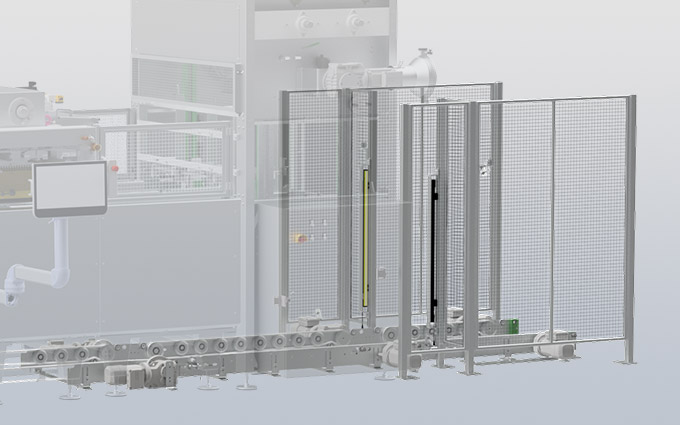

Stacker for starch trays on pallet

- Formation of partial stacks wit partial stacking unit

- Number of trays per partial stack adjustable upon customer's request

- Available in different installation heights

Pallet conveyor stacker for pushing the stacked trays

- Available in two versions: normal or heavy-load design

- Buffer spaces available for pallets after stacker

- Available in three designs: straight, lateral feeding or turntable

Deutsch

Deutsch  English

English  Русский

Русский