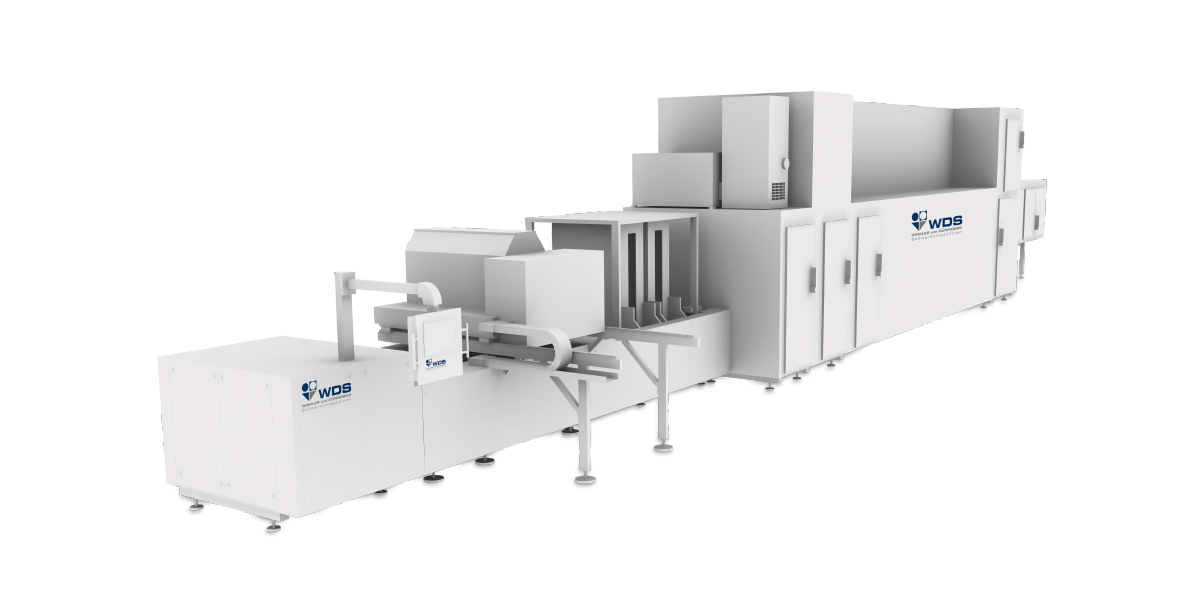

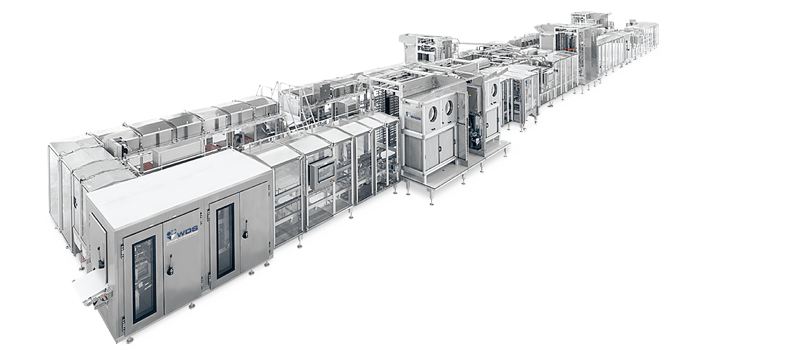

The WDS Candy Wizard Type 163 is a compact, modularly designed plant for the manufacturing of hard candies.

-

Characteristics

- Servo-electrical drives

- Storage memory for almost an unlimited number of recipes

- Frame made of solid aluminum profiles with stainless steel cladding

- Loose-mould system with the well-proven mould carriers

- Continuous product delivery

- Hygienic plant design, easy to operate and to service

-

Technical data

- Plant speed up to 50 moulds / minute

- Mould size of 1052 x 135 x 40 mm

- Coated aluminum mould, one ejector pin per product with return spring

- 4 product rows / mould

- 136 products / mould

- Capacity: up to 6800 articles / min.

- Output exceeding 2 t/h (depending on product weight)

Stations

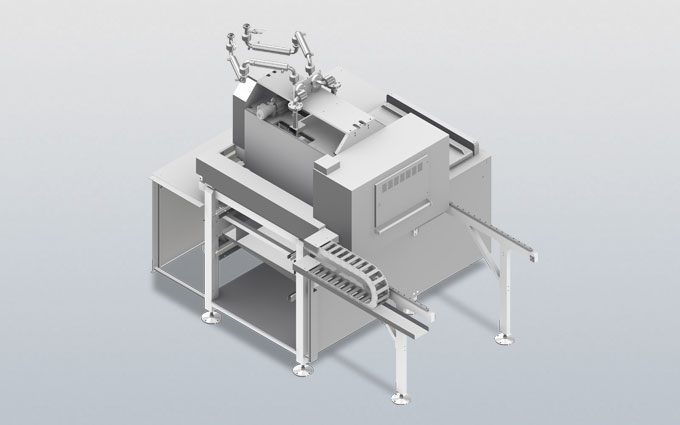

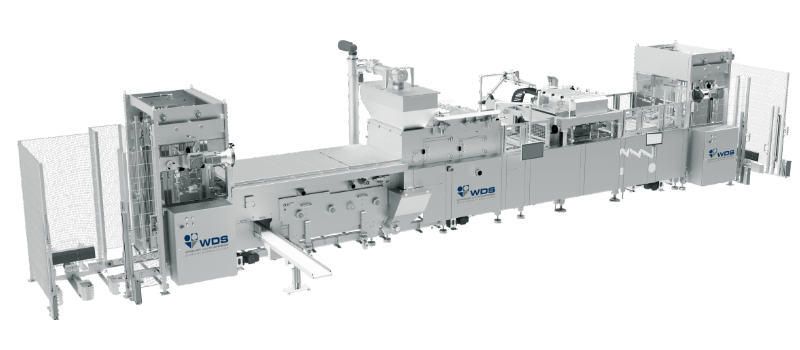

Depositor

- Modular design of the depositor

- The basic equipment is designed for Mono depositing

- Possibility of One-Shot or Triple-Shot depositing by adding further components

- Possibility of thermally insulated pump systems

- Depositing of the entire mould in one depositing stroke

- Movable depositing head

- Depositing head can be pulled out to one side by hand

- Servo-electrical drives

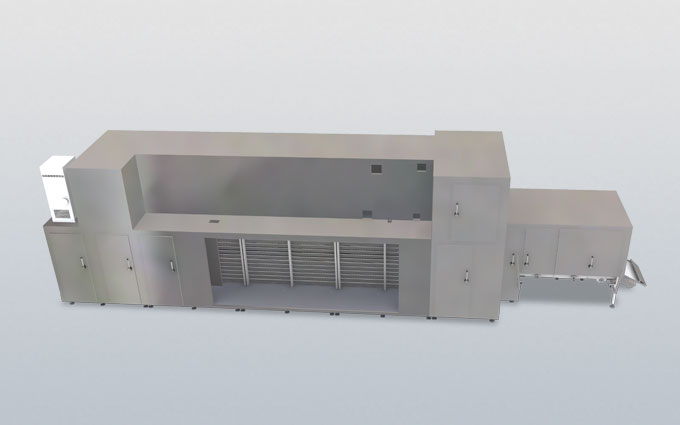

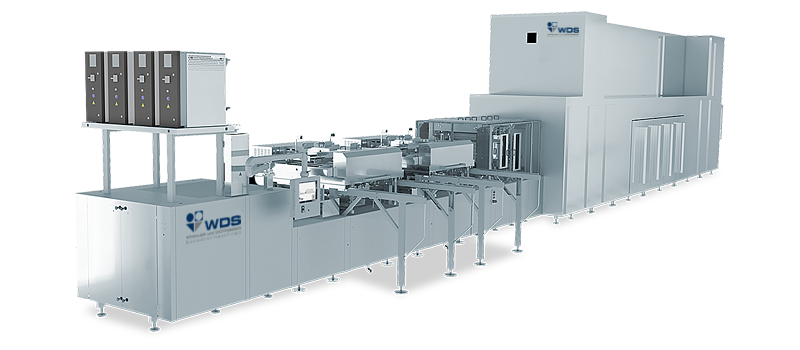

Cooling cabinet / Demoulding station

Layout of the cooling cabinet depends on the required plant speed..

- Mould transport by endless chain

- “Loose-mould-principle”

- Moulds are always aligned horizontally by the mould carrier

- Cooling station integrated in insulation cladding

- Cooling by adjustable cold airflow

- Product demoulding by ejector roller onto discharge wire mesh belt

- Mould returning device

- Product discharge in longitudinal direction of the plant

- Adjustable product discharge height

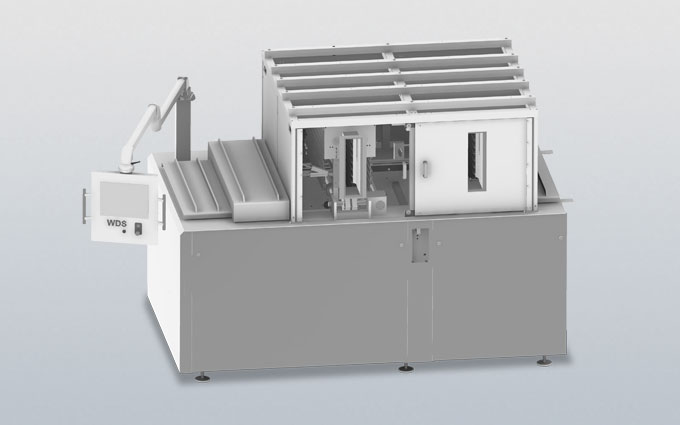

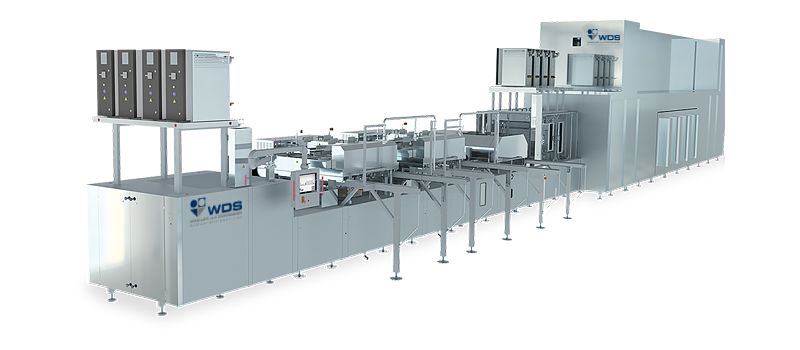

Mould exchanger

For automatic lifting / insertion of moulds incl. empty mould detector.

- Comprising inserting and lifting magazine

- Paternoster principle

- Up to 50 cycles / min.

- Servo-electrical drives

Deutsch

Deutsch  English

English  Русский

Русский