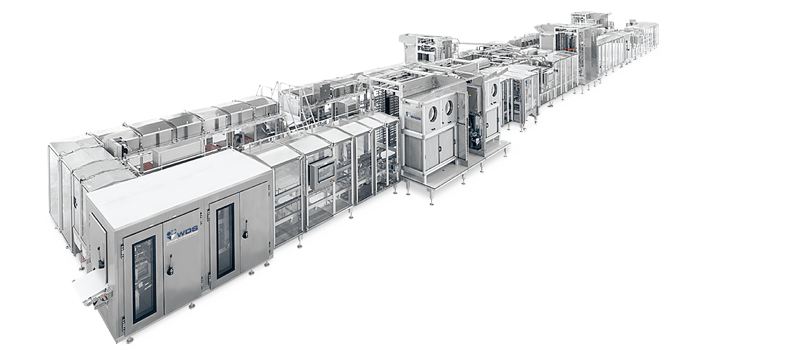

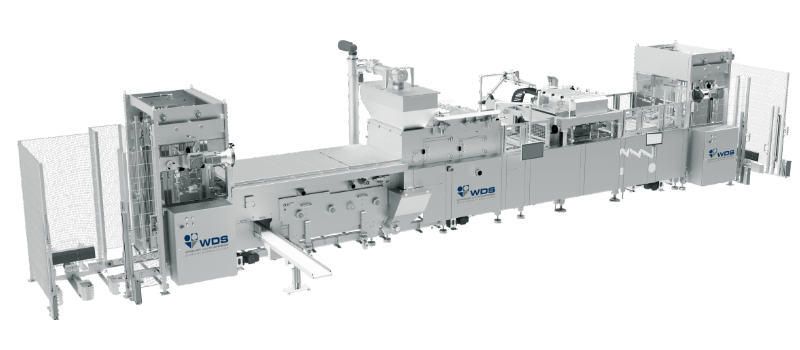

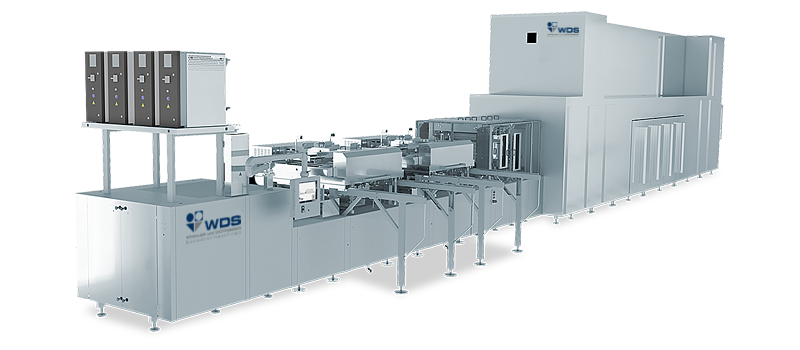

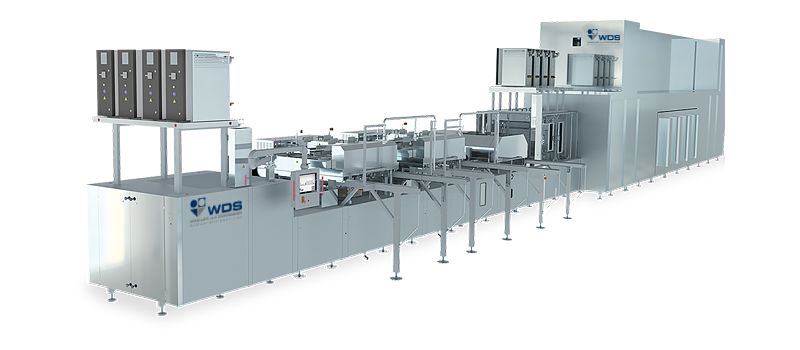

In the WDS steel belt plant the chocolate product is deposited on the cooled steel belt via the depositing station and transported through the cooling cabinet. The chocolate products are unfilled and filled drops, as well as ribbons.

Characteristics:

- Compact, modular production line with good access thanks to the functional design of the units

- Half cooler length thanks to the cooling "upside down" on the returning steel belt

- Significantly reduced cooling time thanks to the high thermal conductivity of the steel belts

- Maximum endurance and robustness thanks to the stainless steel pump system

- Reduced cold losses through good cooling cabinet insulation

- When the working width is large, divided rotary valves (easy handling)

- Removable depositor and vibration unit

-

Technical data

- Up to 350,000 drops/min or 3,000 kg/h

- Mono, One-Shot or Triple-Shot

- Depositing cycles: up to 40 cycles/min

- Width of steel belt: 800, 1,000, 1,200 or 1,500 mm

- Multiple separate cooling zones

Deutsch

Deutsch  English

English  Русский

Русский