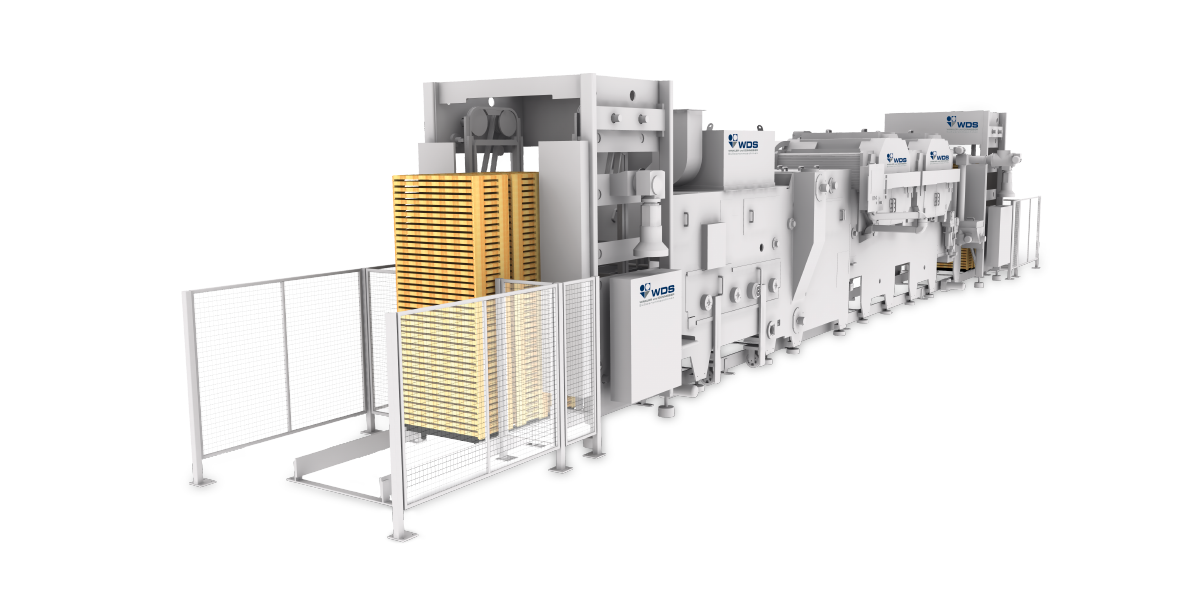

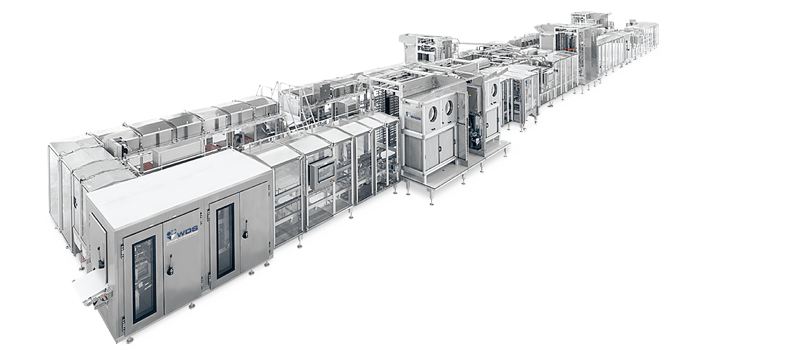

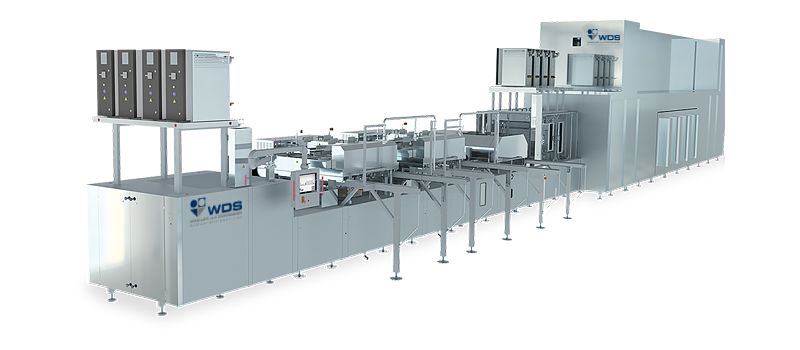

Plant for the manufacture of all starch-moulded products such as jelly and gum (on pectin basis, gum arabic, gelatine, agar-agar, carrageenan) as well as liquorice, fondant, cream, marshmallow foam and similar items. Furthermore, the equipment is suitable for depositing liqueur.

-

Characteristics

- Optional continuous or intermittent starch tray transport – depending on the product requirements

- Large selection of depositors, two-stroke or full tray technique, Mono, One-Shot, Starlight with filling

- Brushless execution of the complete plant

- Extractable sifting unit with separation and cleaning sieve

- Depositing chain outside the product area

- High plant availability

- Low maintenance i.e. by programmable single servo-electrical drives

- Execution in accordance with explosion prevention

- Easy operation and highest hygienic level

-

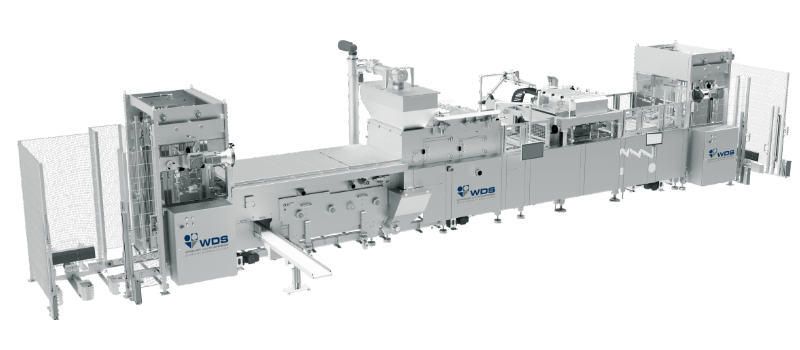

Technical data: Type 462B/1

- Plant speed up to 32 trays / min

- Working height 1340 mm / 1370 mm

- Tray dimensions 760 - 840 x 360 - 440 mm

- Stacking height starch trays up to 3200 mm

- Steel pallets for 2 or 3 stacks

- Up to 12 colours/flavours each depositor

- Pump system depending on product data, i.e.

- Full-tray system up to 22 x 38 pistons

- Multiple stroke system up to 14 x 42 pistons

-

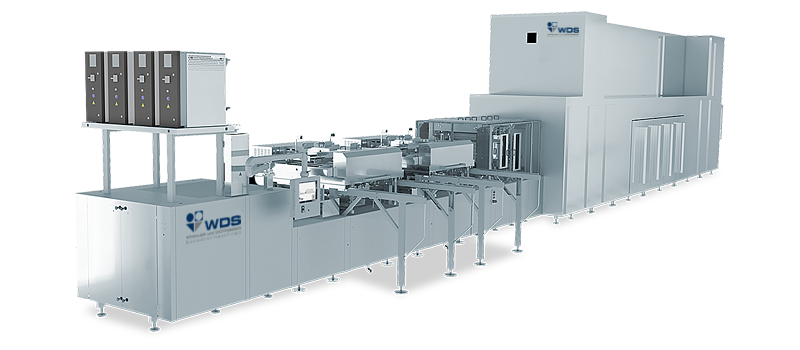

Technical data: Type 462CL

- Plant speed up to 35 trays / min

- Working height 1410 mm

- Tray dimensions 1160 - 1240 x 360 - 440 mm

- Stacking height starch trays up to 3200 mm

- Steel pallets for 2 or 3 stacks

- Up to 12 colours/flavours each depositor

- Pump system depending on product data, i.e.

- Full-tray system up to 22 x 56 pistons

Stations

Pallet conveyor

- Straight feed

- Lateral feed

- Feed via rotary plate

- Connection to automatic transport systems

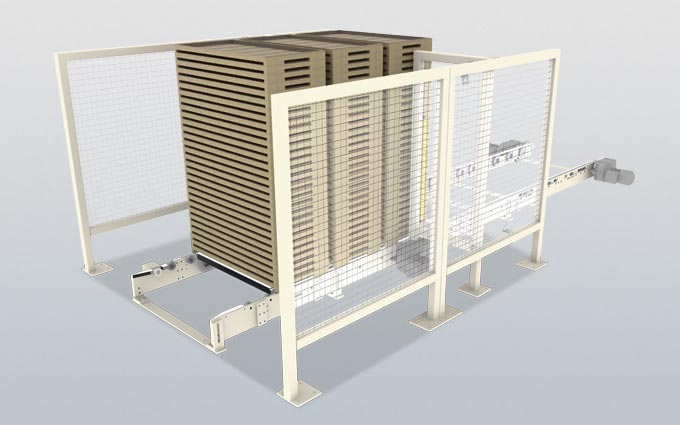

Starch tray loader with destacker

- The pallets with tray stacks are transported automatically into an unloading position of the loader.

- Both chains running right and left in the frame guides, are fitted with grippers

- In each cycle one pair of grippers catches a stack of up to 7 starch trays.

- The starch trays are taken out by a lift latch device from the starch tray pack and put into the transport system of the Mogul plant.

- Maximum stacking height is 3300 mm.

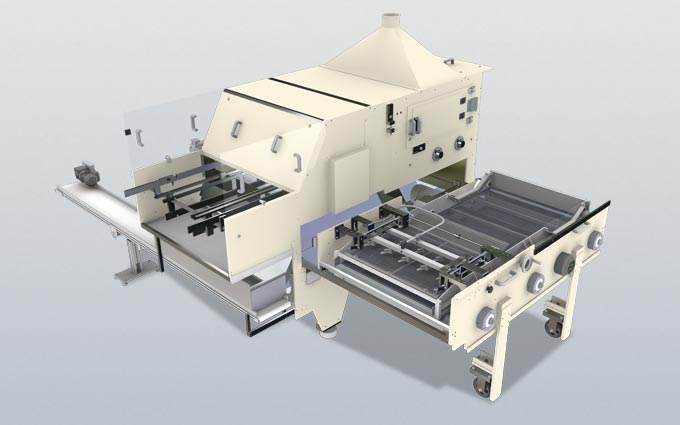

Starch buck, tray tipping and depowdering device

- Starch tray tipper. 360° turning unit in 2 working strokes, thus giving the trays enough time to be emptied even at high working speeds.

- Integrated product outlet conveyor, placed across the plant’s running direction and delivering the products at wish to the operator’s side or to the drive side.

- Screw conveyors transporting the starch powder from under the tipping unit into the starch tray filling station respectively to the starch conditioning unit possibly connected to the Mogul plant.

- Extractable sifting station

- Sifting unit with upper sieve for separation of the products from starch powder and lower sieve for cleaning of starch powder driven by frequency-controlled eccentric motors.

- The complete sifting unit and product cleaning unit can be extracted laterally from the basic machine for maintenance and/or cleaning purposes.

- Pneumatic product pre-cleaning unit is integrated in the sifting unit.

Starch tray filling and printing section

- Circulating conveyor device (conveyor screws) which is transporting and uniformly spreading the starch powder into the tray. Excess powder is recirculated.

- Starch powder compression by adjustable blades.

- Servo-electrically controlled stamping operation with tray cleaning.

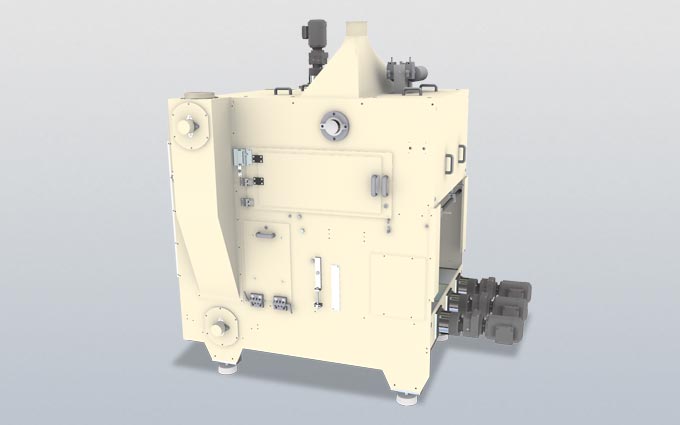

Depositors

- Multiple-stroke depositors

- One-Stroke Mono depositors

- One-Stroke One-Shot depositors

- One-Stroke Starlight with filling depositors

- Depositors laterally extractable

- Depositors in “EasyClean” execution

Stacker with part stacker

- The starch trays are taken out by a lift handle device from the chain and put on top of one another in the magazine.

- Afterwards the tray stack is taken by a pair of grippers and repositioned onto the pallet.

Deutsch

Deutsch  English

English  Русский

Русский