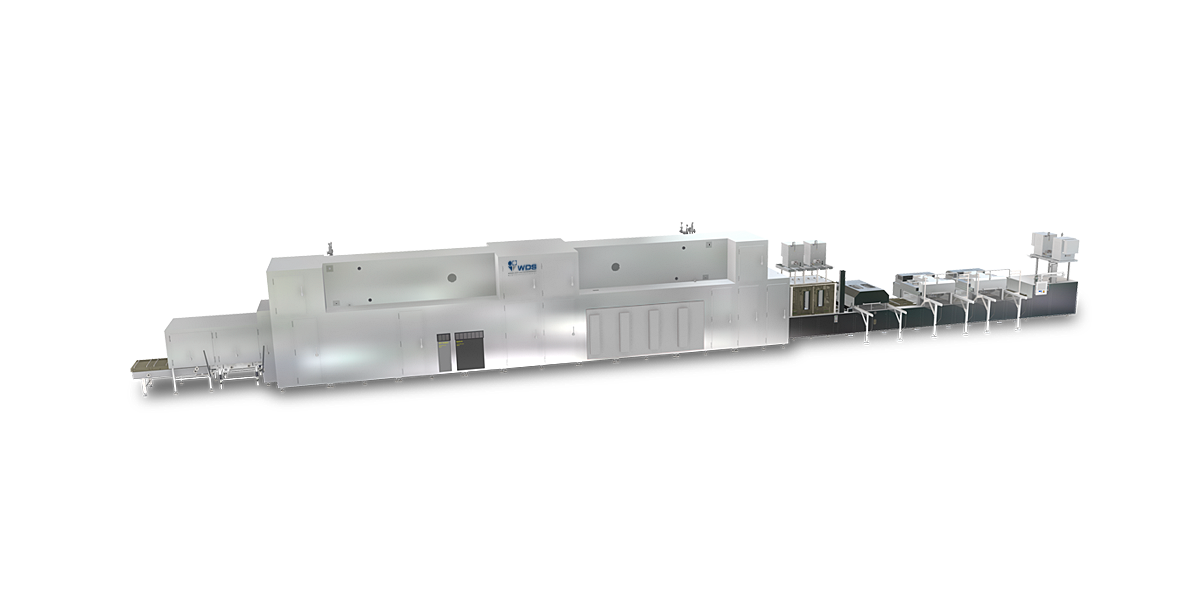

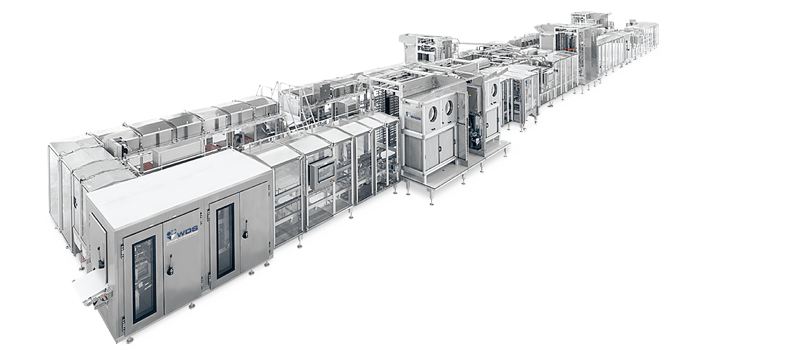

The compact, modularly constructed depositing plant, type 165, is designed for the production of fondant, toffee, pectin and carrageen products.

-

Characteristics

- Servo electrical drives

- Memory capacity for almost unlimited number of recipes

- Frame construction of aluminium solid profiles with allied steel coating

- Loose mould line with well-proven mould supports

- Continuous product discharge

- Hygienic and easy handling line conception

-

Technical data

- Speed of line up to 50 moulds / min

- Mould size 1052 x 165 x 40 mm

- Plastic frame with consolidated silicone inserts, lateral guides are part of the plastic frame

- Capacity up to 2 t / h (depending on product weight and geometry)

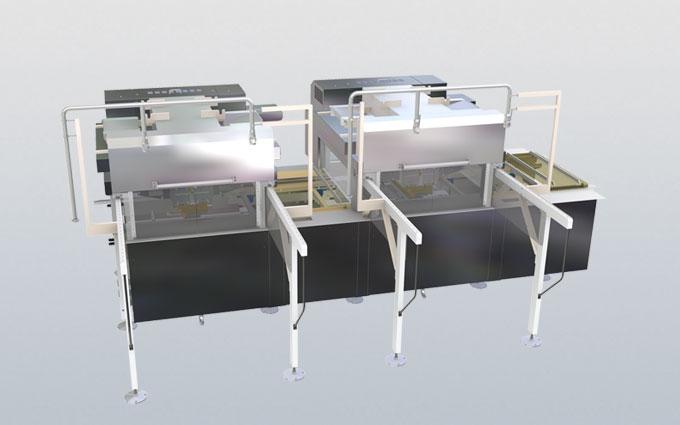

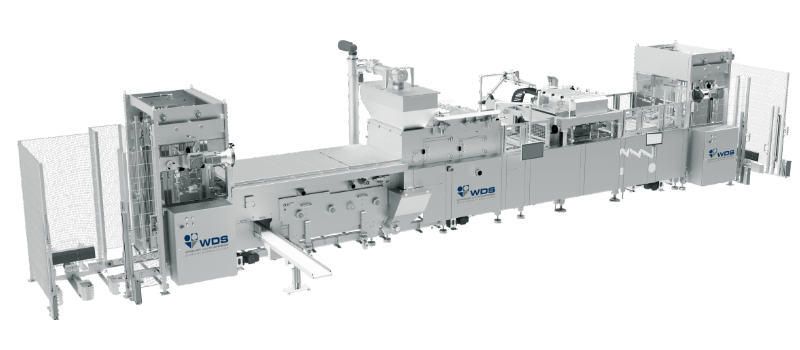

Depositing station

- Modular construction of the depositor.

- Basic equipment is designed for mono-depositing.

- Adding further components, One-Shot or Triple-Shot depositing is possible.

- Thermal separation of the pump system is possible.

- Deposit of complete mould with one depositing stroke.

- In-line movement of hopper.

- Hopper can be removed to the side.

- Servo electrical drives

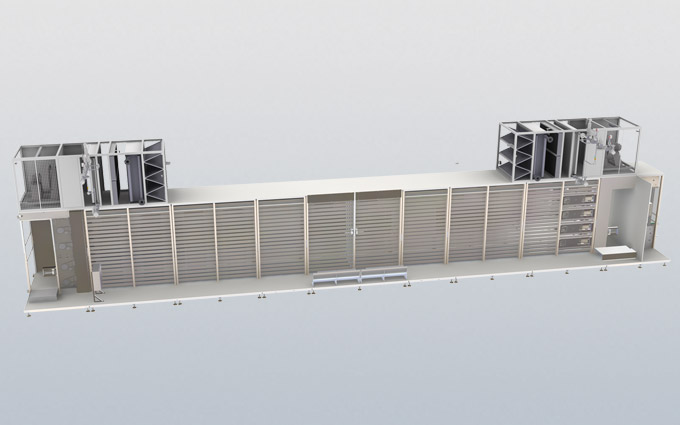

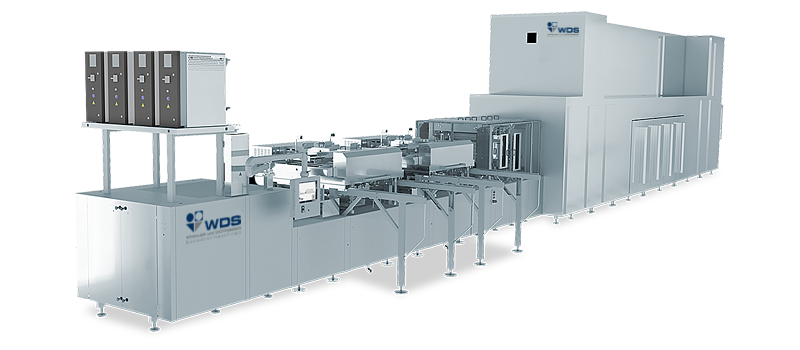

Cooling cabinet

Layout of the cooling cabinet according to desired speed of line.

- Mould transport by endless chain

- Loose mould principle

- Mould supports keep moulds always in horizontal position

- Cooling station integrated in insulation cladding

- Cooling by adjustable cold air stream

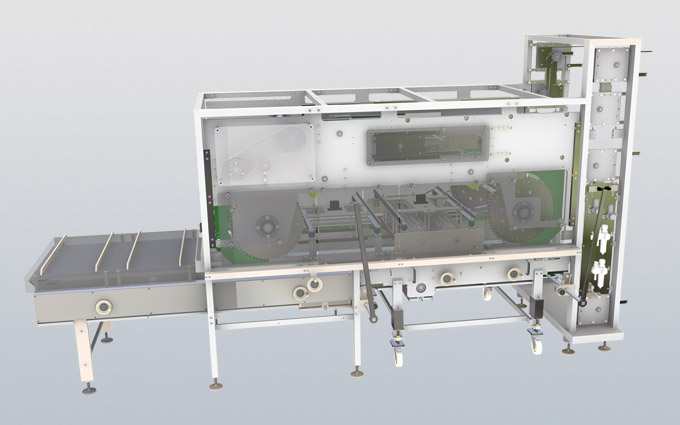

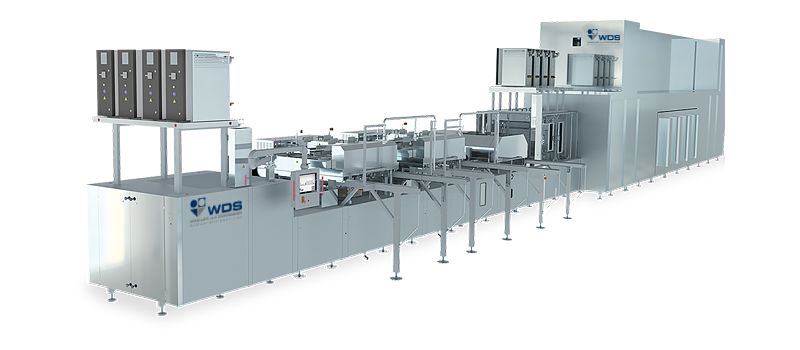

Demoulding station

- Demoulding of product by ejection roller on discharge belt

- Mould return

- Discharge of product in longitudinal direction of line

- Adjustable height of product discharge

- Demoulding station laterally extractable

Mould exchange station

Consisting of insertion and removal magazine.

- Consisting of insertion and removal magazine

- Paternoster principle

- Up to 50 cycles / min

- Servo electrical drives

Deutsch

Deutsch  English

English  Русский

Русский