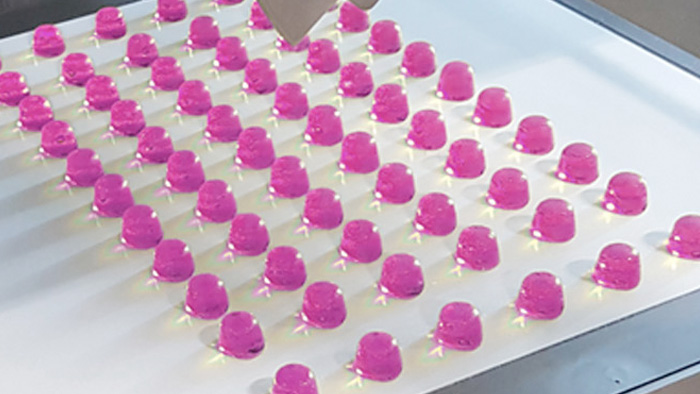

ConfecECO was specially developed for up-and-coming companies and manufacturers who are looking to increase their productivity while placing their trust in the well-known WDS quality. Solid and filled products made of gum and jelly – with and without additives – can be produced up to a capacity of approx. 100,000 pieces/hour, depending on product weight and size. The plant concept incorporates three possible expansion stages: starting with automated mass dosing, followed by automated cooling, up to a complete production line with a product demoulding unit. The modular design of ConfecECO allows the plant to be upgraded to higher levels of automation or expansion at a later date.

sweetOTC

Succeed in the market for dietary supplements and over-the-counter medicines with trendy, tasty and active effective OTC confectionery.

ConfecECO is a plant for the production of OTC confectionery, taking into account all relevant hygienic aspects. It can also be customised specifically to meet your requirements.

Chocolate

Variants

-

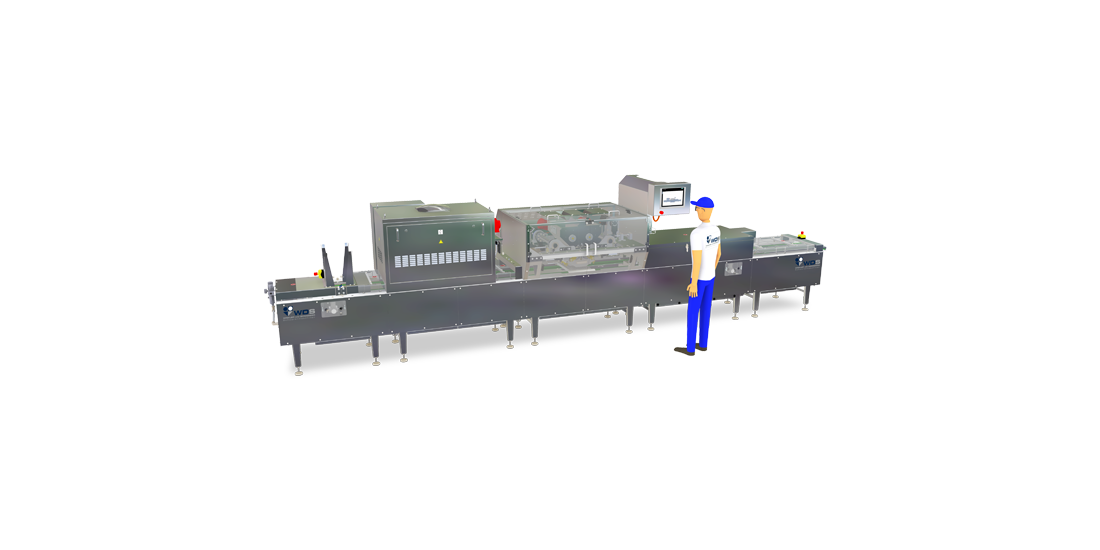

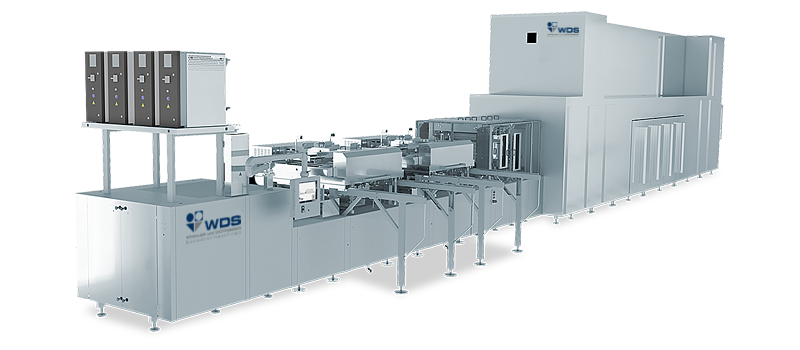

ConfecECO-D

For anyone who wants to get started in automated production while retaining manual work steps.

- Manual mould feeding

- Spraying of the mould cavities

- Depositor section:

- Dosing method: "Mono"; optional: "One-Shot"

- Types of dosing: spot deposit or ribbon deposit

- Lifting table: pneumatic; optional: servo-electric

- Mould transfer to manual removal

-

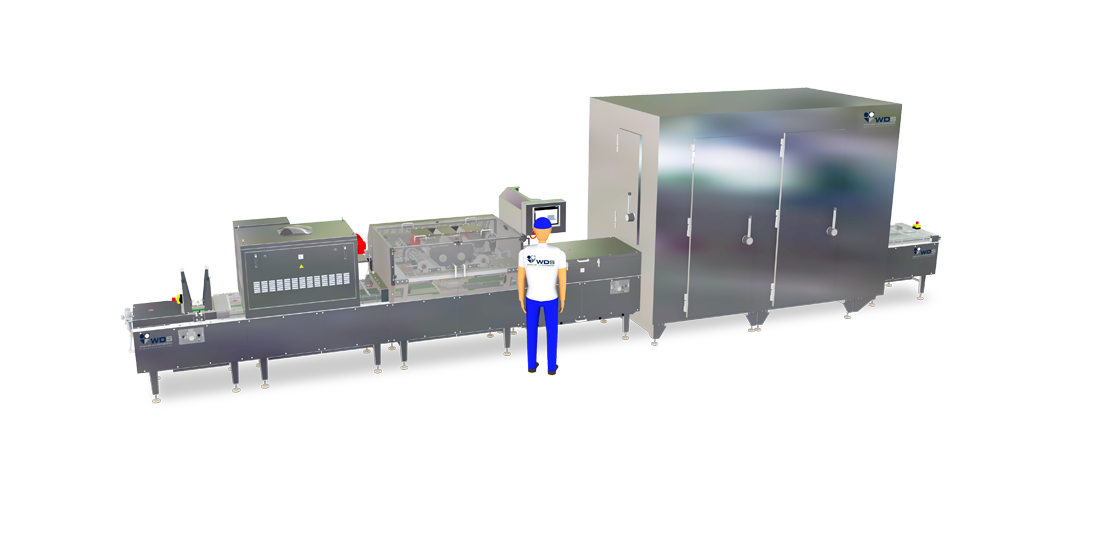

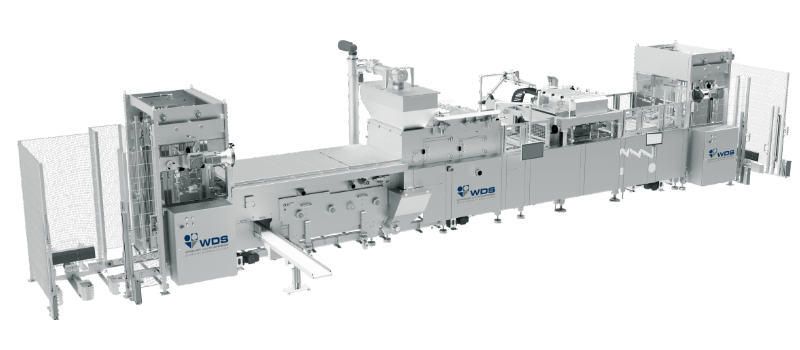

ConfecECO-DC

Automated production with manual work steps but integrated cooling unit.

- Manual mould feeding

- Spraying of the mould cavities

- Depositor section:

- Dosing method: "Mono"; optional: "One-Shot"

- Types of dosing: spot deposit or ribbon deposit

- Lifting table: pneumatic; optional: servo-electric

- Cooling of deposited products

- Mould transfer to manual removal

-

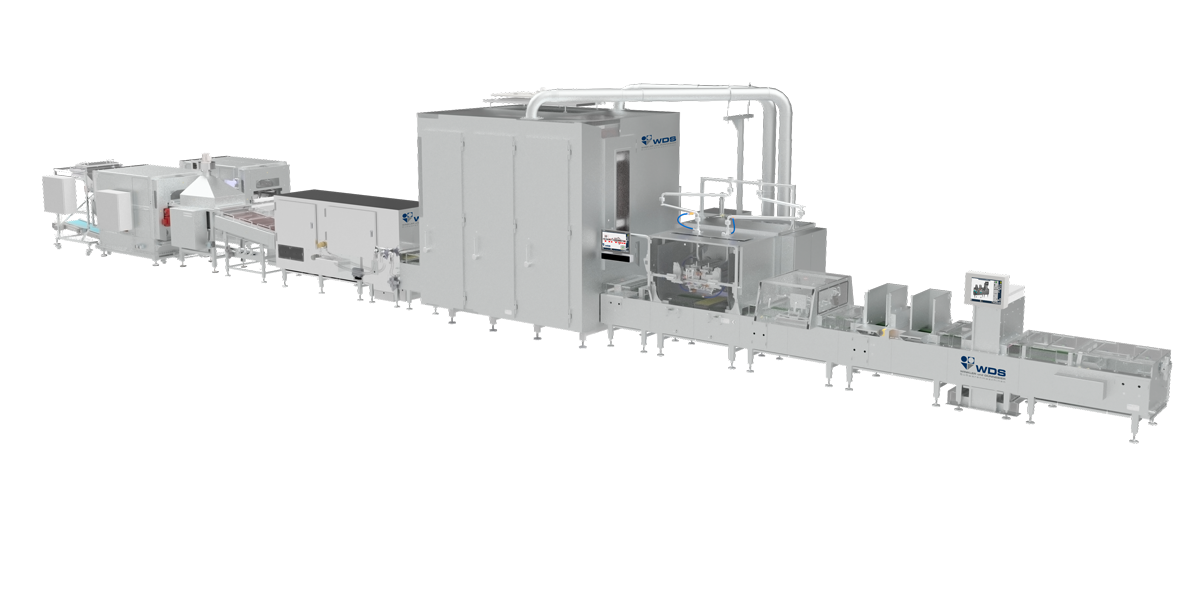

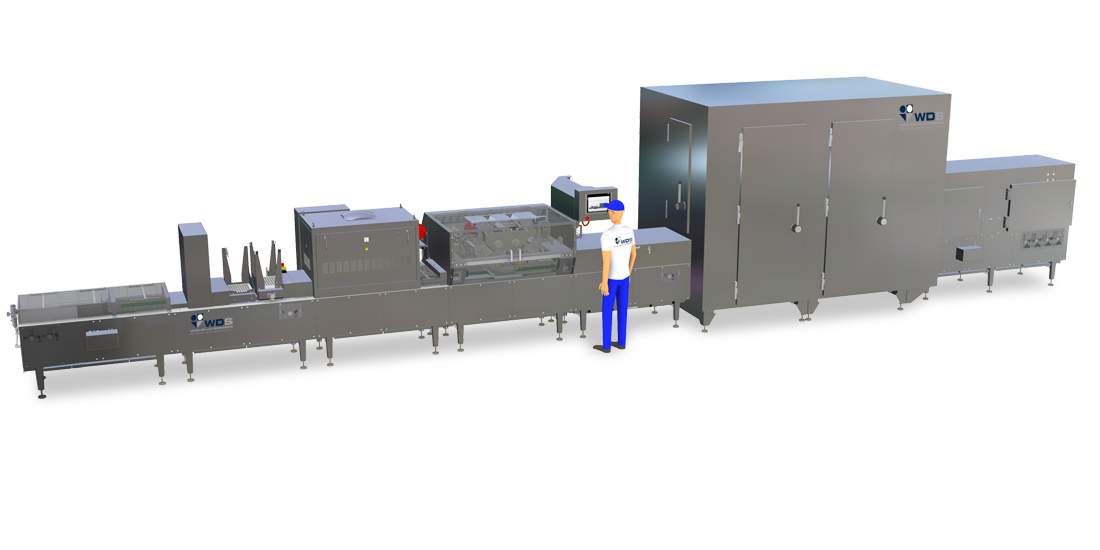

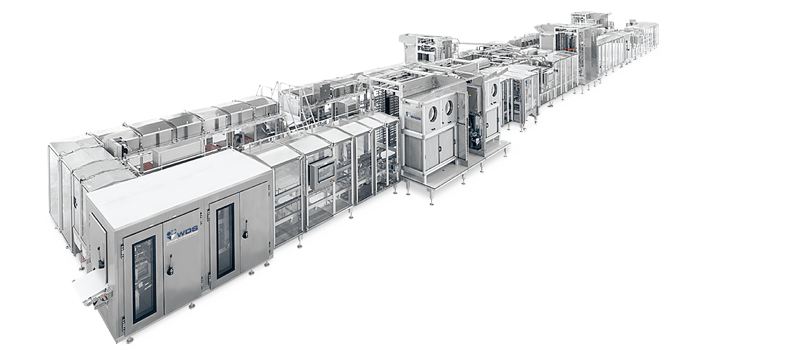

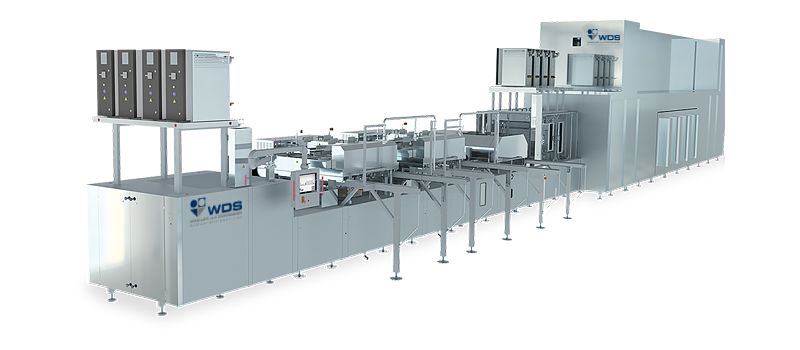

ConfecECO-DCM

For anyone who wants to replace manual mould handling and product demoulding work steps with a completely automated production line.

- Mould feeding via mould exchanger

- Spraying of the mould cavities

- Depositor section:

- Dosing method: "Mono"; optional: "One-Shot"

- Types of dosing: spot deposit or ribbon deposit

- Lifting table: pneumatic; optional: servo-electric

- Cooling of deposited products

- Automated, well-ordered product demoulding

- Mould exchange section with optical mould empty check; optional: with automatic inserting and lifting magazine

- Automatic mould circuit

-

Technical data

ConfecECO

- Output: up to 250 kg/h

- Mould size: 425 mm x 275 mm x 30-40 mm

- Mould material: Polycarbonate, Silicone, Blister optional

- Speed: 10 moulds/minute

ConfecECO-XL

- Output: up to 700 kg/h

- Mould size: 640 mm x 275 mm x 30-40 mm

- Mould material: Polycarbonate, Silicone, Blister optional

- Speed: 10 moulds/minute

ConfecECO Highlights

Highly flexible

thanks to modular production line in 3 expansion stages (upgrade possible at any time).

Wide range of production possibilities

for gum and jelly confectionery.

Extractable depositor section

Good accessibility, hygienic production.

Well-ordered demoulding

Well-ordered demoulding onto a discharge belt that is gentle on the product.

Compact design

Effective production with reduced space requirements.

Deutsch

Deutsch  English

English  Русский

Русский