Perfect accessibility and the highest level of hygiene

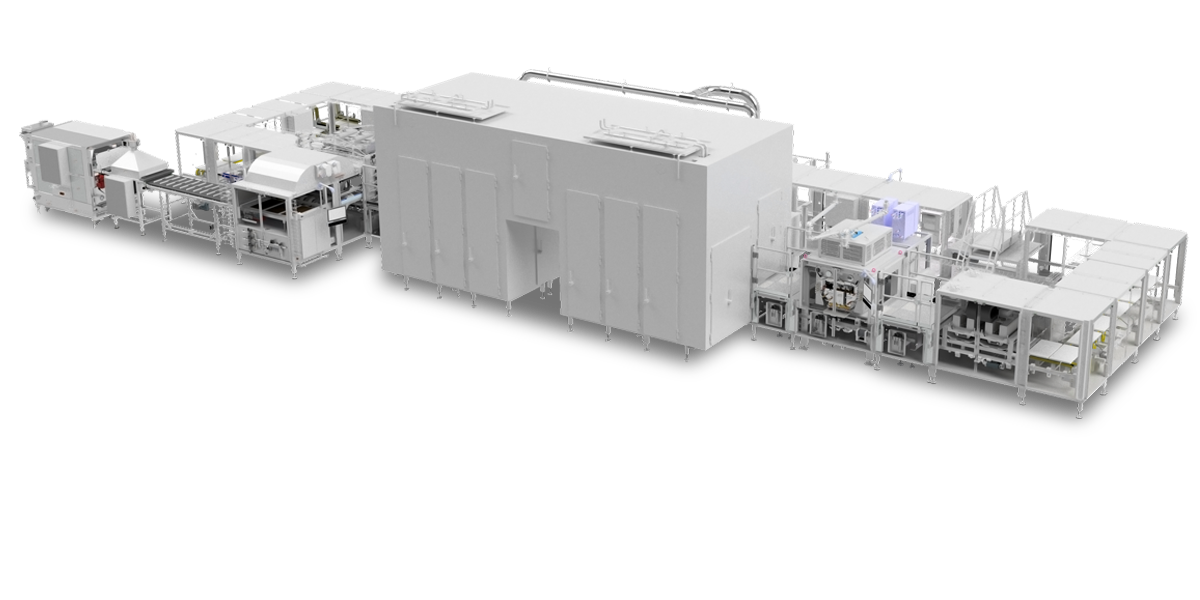

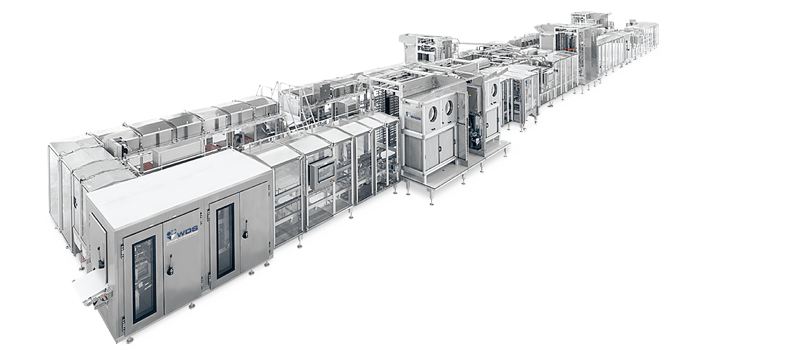

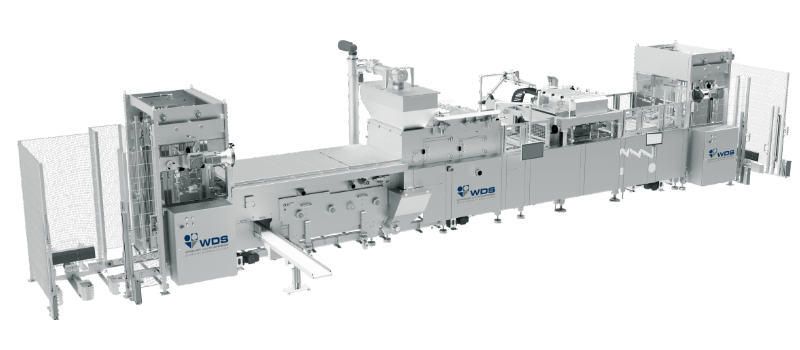

The WDS ConfecPRO moulding plant is designed for moulding filled and solid gums & jellies at medium to high production rates. The modular, highly flexible production line can be configured for a variety of tasks in one or two lines, at ground level or over several floors.

Intelligent down to the last detail

The modular design of the WDS ConfecPRO makes it possible to adapt or extend the plant at any time based on the customer's changing requirements. The decentralised control concept allows sections to be added easily, especially when free spaces are scheduled. This flexibility, and the large number of available aggregates, makes it possible to realise the widest possible product range.

Gum & Jelly

The modular design of the WDS-ConfecPRO makes it possible to adapt or extend the plant at any time based on the customer's changing requirements. The decentralised control concept allows sections to be added easily, especially when free spaces are scheduled. This flexibility, and the large number of available aggregates, makes it possible to realise the widest possible product range.

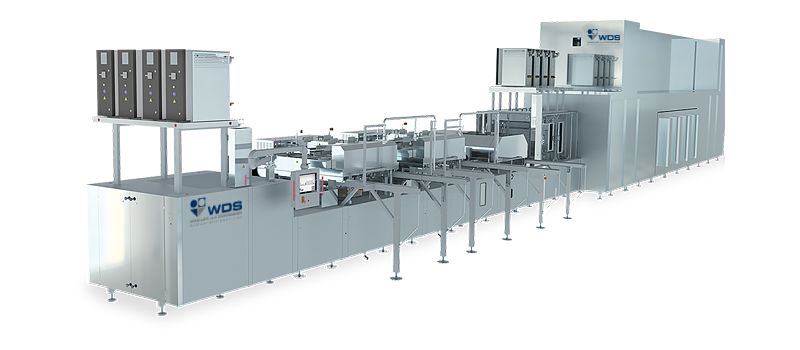

sweetOTC

Succeed in the market for dietary supplements and over-the-counter medicines with trendy, tasty and active effective OTC confectionery.

ConfecPRO is a plant for the production of OTC confectionery, taking into account all relevant hygienic aspects. It can also be customised specifically to meet your requirements.

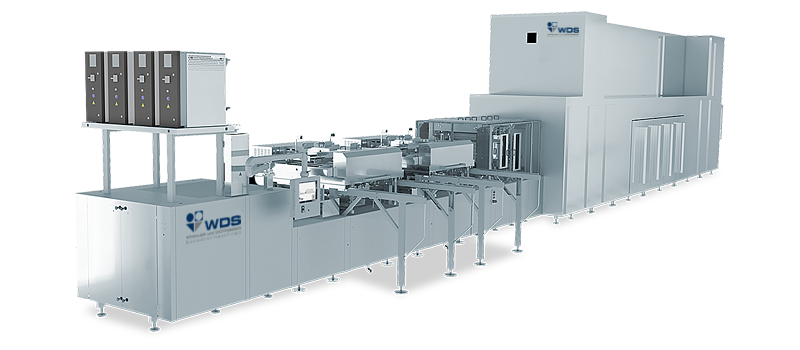

Chocolate

Launch a new dimension in chocolate production with the ConfecPRO. With the moulding plant, you can produce filled or solid chocolates with or without additives. The highly flexible production line offers maximum moulding accuracy, EasyClean designs and short changeover times for the confectionery production of tomorrow.

-

Features

- Loose mould plant for fast mould exchanges without tools

- Spraying:

- Precise spraying into the product cavities only (prevents unnecessary contamination of the moulds)

- Low spray volume per cavity for best possible sugaring or oiling of the end product

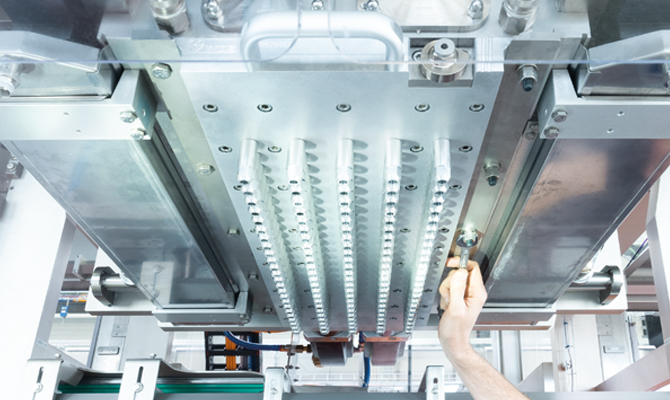

- Depositing:

- Maximum depositing accuracy thanks to precision in-house manufacturing and wear-resistant materials

- Very short dwell times of the mass until depositing.

- WDS SmartPipe technology permits weight-accurate depositing of viscous recipes (high Brix masses); no traditional open mass hoppers

- SmartPipe permits fast, effective and fully automated cleaning

- Cooling:

- Immediate cooling after depositing without mould removal

- Space-saving cooling thanks to the paternoster principle

- Targeted air routing and humidity control for optimum results

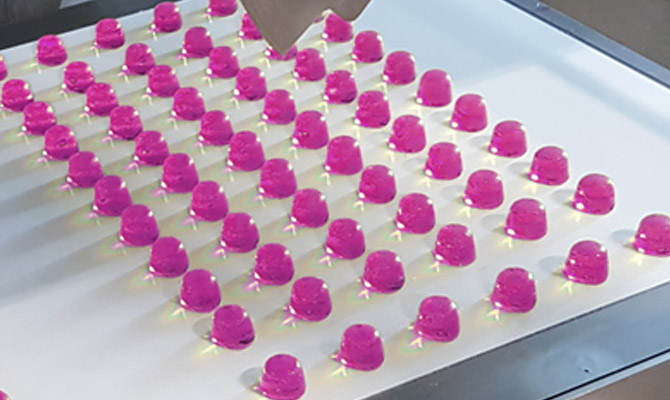

- Demoulding:

- Well-ordered demoulding to prevent products from sticking together

- Well-ordered shaping maintained into the product post-treatment stage

- Gentle product handling

- Fulfils the highest hygiene requirements (option: as a validated plant)

- Fast on-site installation and easy extension thanks to the decentralised control principle and modular components

-

Technical data

- Mould size 860 mm x 450 x max. 35 mm

- Plant speed up to 25 moulds/min

- Output at 5.5 g/product up to 3.8 t/h (depending on product and speed)

- Working height 1 000 mm

ConfecPRO Highlights

Operator touch panel

Intuitive operation and recipe memory.

Depositing tool

Comfortable change of the nozzle plate.

Cooling cabinet

Upward and downward part (2 zones).

Transport

Optimum accessibility.

Depositor section

Extractable.

Well-ordered demoulding

Well-ordered demoulding onto a discharge belt that is gentle on the product.

Deutsch

Deutsch  English

English  Русский

Русский