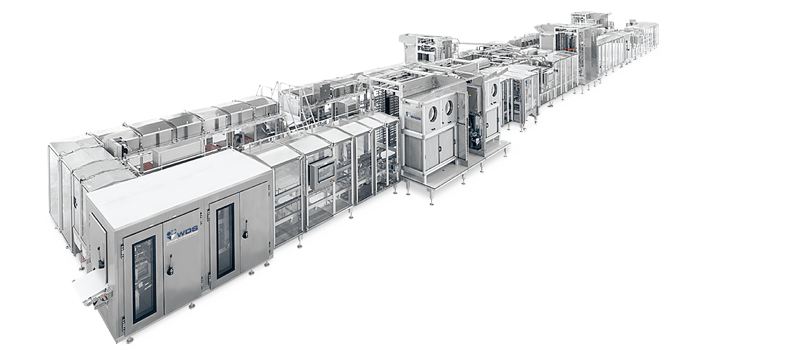

Chocolate or jelly – with and without filling! With just one versatile WDS plant, you'll cover the entire product spectrum of a wide variety of confectionery products!

The flexible plant concept of ConfecVARIO ensures an extremely flexible and efficient production of your confectionery products. The modular design allows a variety of different plant layouts, each of which can be optimally adapted to the production conditions. To ensure that plant sections are used in the best possible way, the overall speed of the plant is not determined by the slowest process, but is flexibly adapted to the various sections.

The availability of the plant is particularly high, as maintenance, repairs and cleaning can be carried out during ongoing production. Individual sections of the plant continue production without interruption during this time.

Chocolate

The innovative machine concept of ConfecVARIO makes it possible to produce a wide variety of chocolate articles. Produce filled or solid chocolates with and without additives on the chainless plant. The highly flexible production line enables precision depositing, EasyClean designs and absolute flexibility.

Gum & Jelly

With ConfecVARIO, you can produce a wide variety of gum and jelly products. Produce hygienically in polycarbonate moulds, dose with the highest possible depositing accuracy, and shape the products in a gentle and organised manner.

sweetOTC

Succeed in the market for dietary supplements and over-the-counter medicines with trendy, tasty and active effective OTC confectionery.

ConfecVARIO is a plant for the production of OTC confectionery, taking into account all relevant hygienic aspects. It can also be customised specifically to meet your requirements.

-

Highlights

- Wide variety of chocolate and/or jelly products

- Flexible plant layouts thanks to modular design

- Maintenance and cleaning during operation

- Innovative transport system takes over additional functions such as lifting, vibration or ribbon depositing movements

- Chainless mould conveyor for maximum hygiene and cycle independence

- VarioCABINET: Individual shelves in the cooling cabinet that can be removed without tools

- Optimum accessibility

- Unrestricted process observation

- Very short changeover times

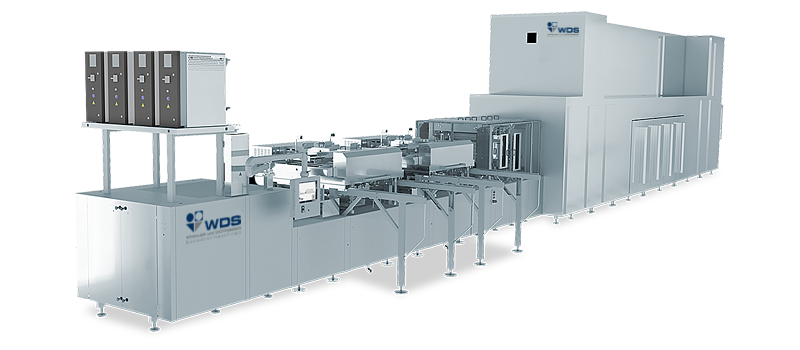

Multifunctional.

Variable dwell times for cooling, warming, holding and buffering of products.

Highlights

Set-up:

- The moulds are loaded and unloaded from a rotating rack system by gantry kinematics

- Chainless design

Process:

- Freely selectable dwell times

- Optimised airflow thanks to modern airflow simulation

- Constant, reproducible cooling results on all levels

Cleaning:

- Easy accessibility to all areas of the VarioCABINET

- Shelves can be removed from the VarioCABINET without tools

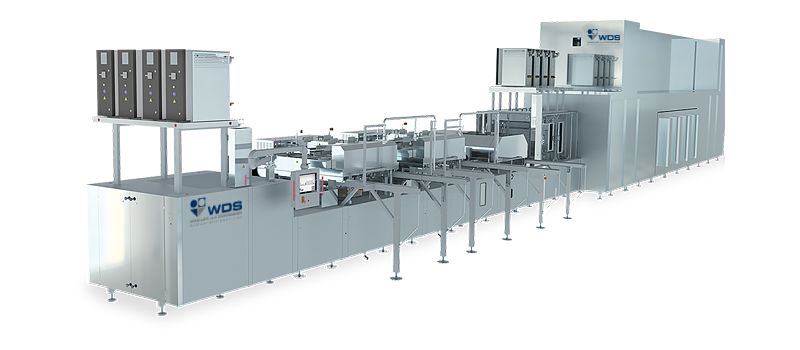

Mould carrier with integrated lift & vibration function

High-precision depositing with simplified lifting of the mould. Immediate vibration, e.g. directly after depositing.

Highlights

- VarioVIBRATION:

- Horizontal, vertical and combined vibration during and immediately after the depositing process

- Noiseless vibration without insulation cladding

- VarioLIFT: The mould, as the lightest element, is moved under the depositor section.

- VarioDEPOSIT:

- Multiple depositing in rows with lifting function

- Exact positioning of each mould carrier below the rigid depositor head, e.g. for ribbon deposit

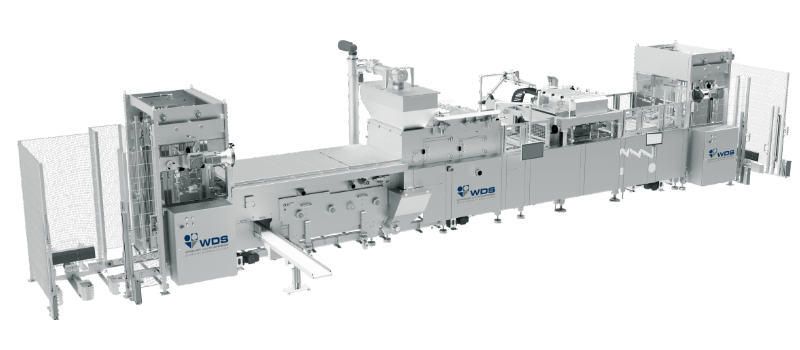

Chainless mould conveyor

VarioTRACK transports individual moulds on a mould carrier. The switch technology enables independent transport of the moulds to different sections of the plant, various speeds and flexible mould grouping and separation. This means that the number of moulds for one plant can be significantly reduced.

Highlights

- Chainless transport: precise movement of individual moulds

- Flexible speeds: No delay due to rigid chain segments

- Innovative, new plant layouts: Switch systems and individual mould conveyors make previously impossible, efficient plant layouts a reality

Deutsch

Deutsch  English

English  Русский

Русский