What you can expect at the WDS stand

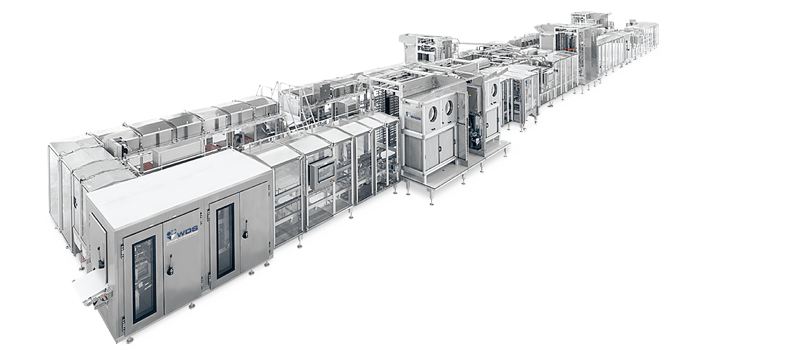

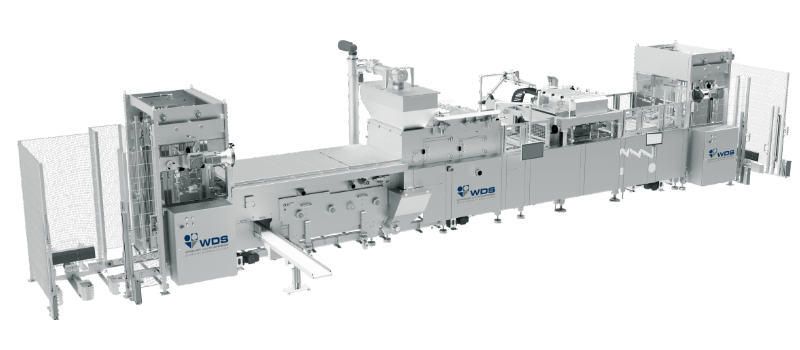

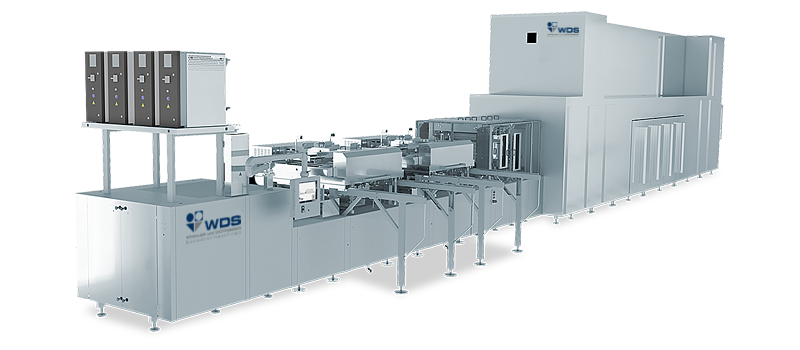

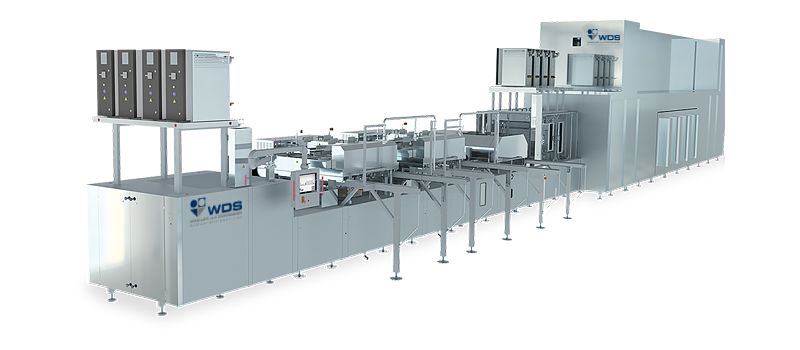

Depositor systems for all depositable and demouldable masses will be presented, reflecting the diversity of WDS plants. From the laboratory scale to the large-scale plant, WDS offers confectionery machines for all capacity and manufacturing requirements. Especially for the OTC sector, WDS presents depositor systems made of hygienic full stainless steel: a true innovation!

Thanks to the EasyClean design of WDS plants and the use of adapted service trolleys, it is easy to change parts that come into contact with the mass as well as to completely replace a depositor system, e.g. for external cleaning or for a large variety of products using exchange systems.

The product- and system-specific program parts demonstrate the extraordinary quality standards of Winkler and Dünnebier confectionery machines. High vertical integration and top-quality material processing are reflected in the dosing and process precision of WDS plants. Last but not least, extensive know-how and many years of experience with various masses and technologies enable WDS to process special masses with sensitive additives in the field of OTC confectionery, supplements and nutraceuticals in a way that is both gentle on the product and reproducible.

Deutsch

Deutsch  English

English  Русский

Русский