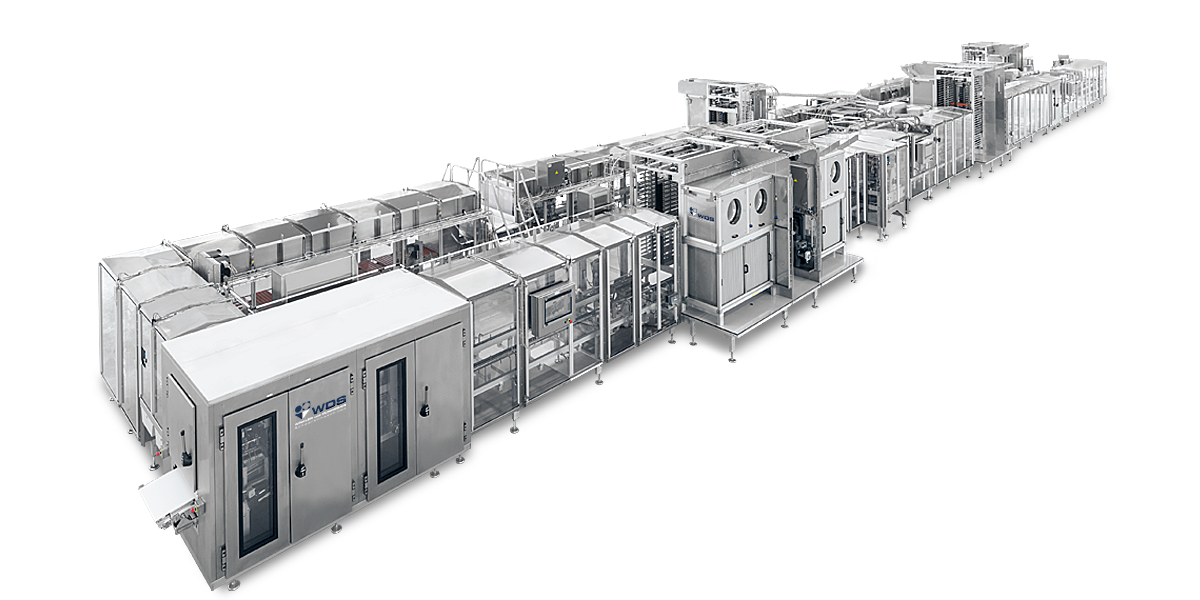

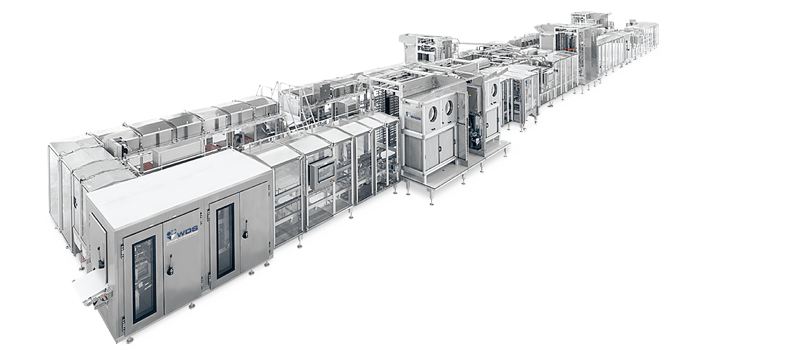

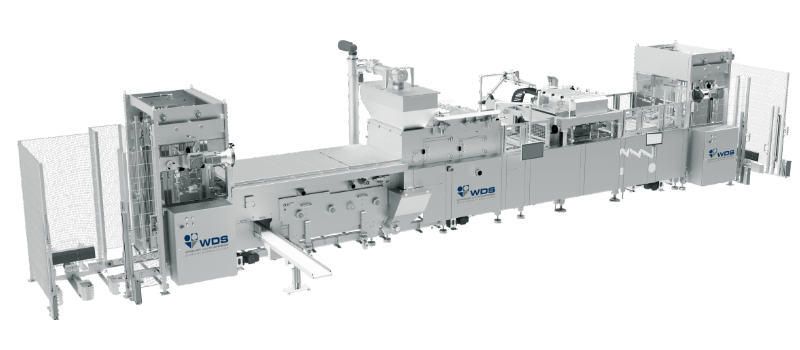

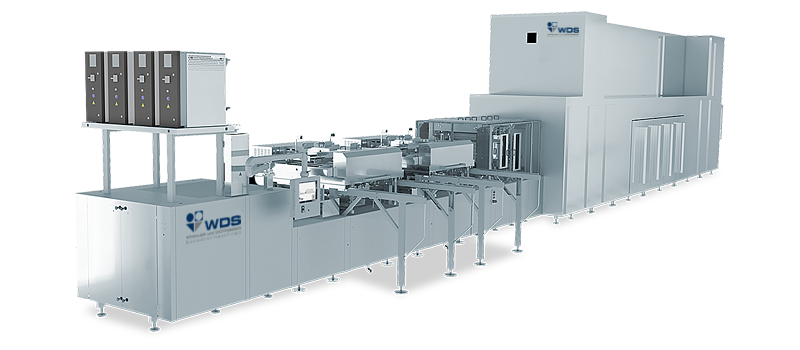

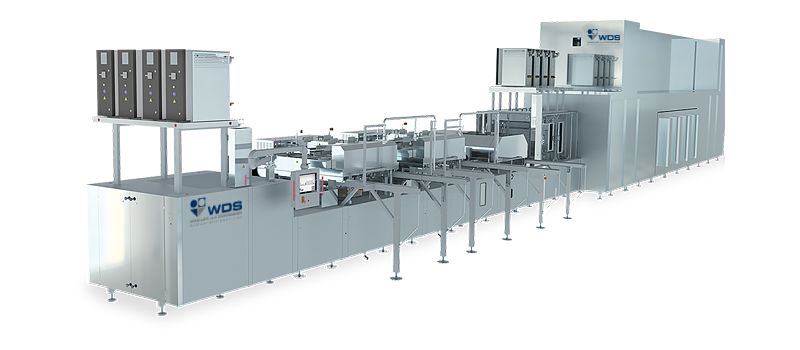

For chocolate production, the ConfecPRO offers a whole range of proven advantages. The concept of the plant is addressed to confectionery manufacturers who want to target a medium to high output quantity – together with a scheduled growth-oriented expansion of the plant right from the beginning. With a plant speed of up to 25 moulds per minute, depending on product, mould size and speed, a production capacity of up to 5,000 kg per hour is possible.

Its design is modular and, together with decentralized electrical control of the plant components, ensures both small expenditure during the initial assembly as well as during later expansion.

Deutsch

Deutsch  English

English  Русский

Русский