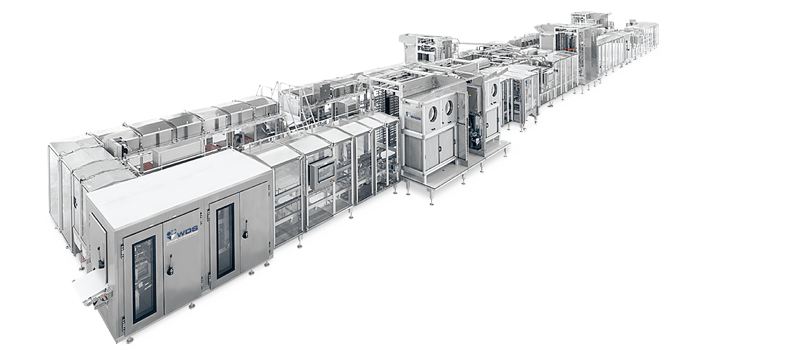

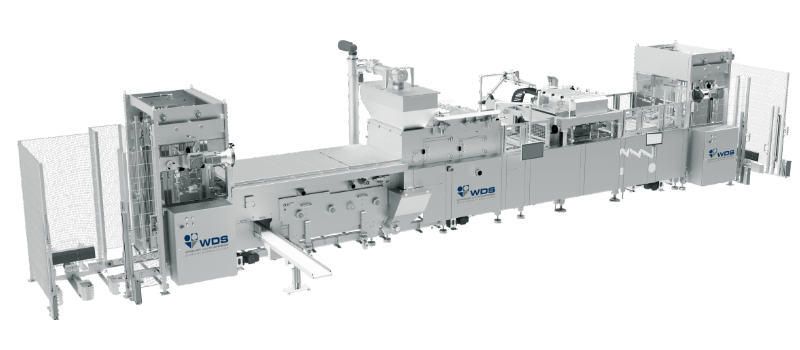

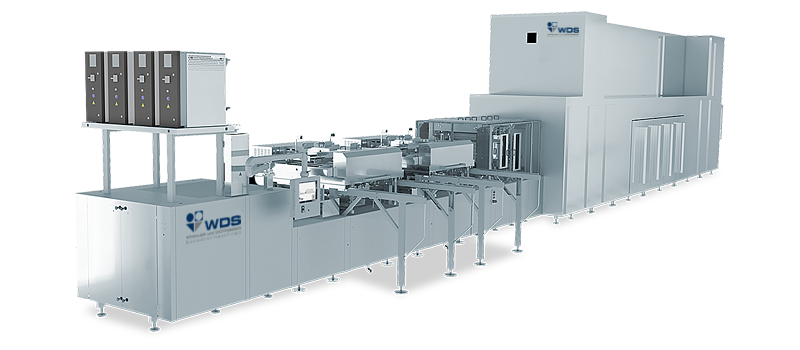

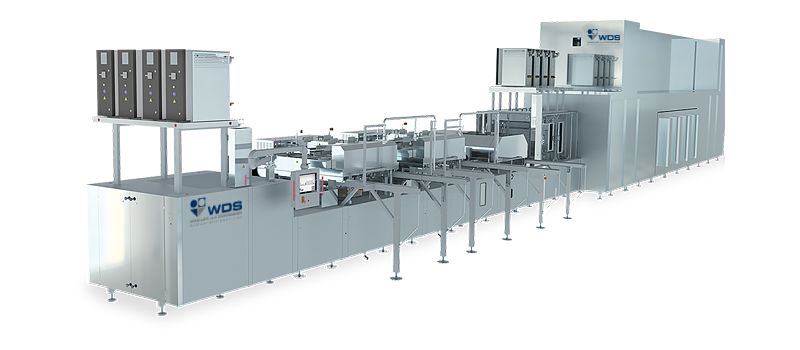

ConfecECO: The entry line into series production

ConfecECO is the entry line into serial production and is aimed at aspiring companies and smaller manufactures. In addition to the production of chocolate products, the ConfecECO series is also suitable for pectin, toffee and fondant products. With a production capacity of up to 600 kg/hour for chocolate and 300 kg/hour for jelly products depending on the mass type, product size and weight, ConfecECO is the ideal machine to fulfil the special requirements of the target group. The range of products that can be produced on this line includes solid and filled sweets of different sizes along with the use of silicone or polycarbonate moulds. This machine type is also suitable for the production of gum and jelly products with added food supplements. A ConfecECO in jelly configuration with post-treatment will be on display at interpack. Orderly demoulding will be demonstrated live.

Deutsch

Deutsch  English

English  Русский

Русский