WDS SmartDevices

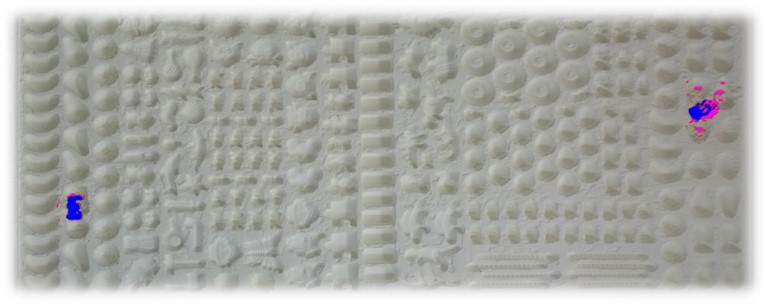

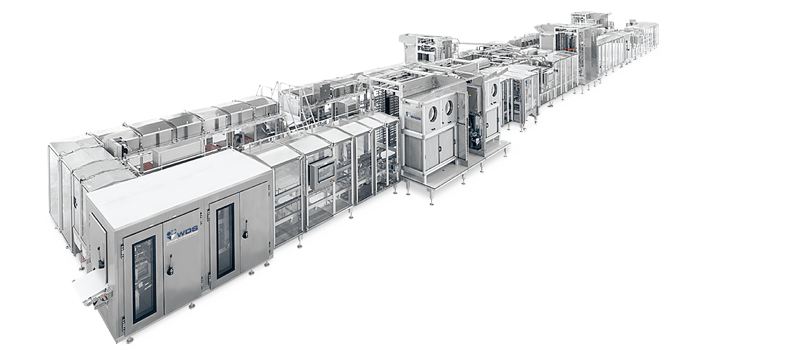

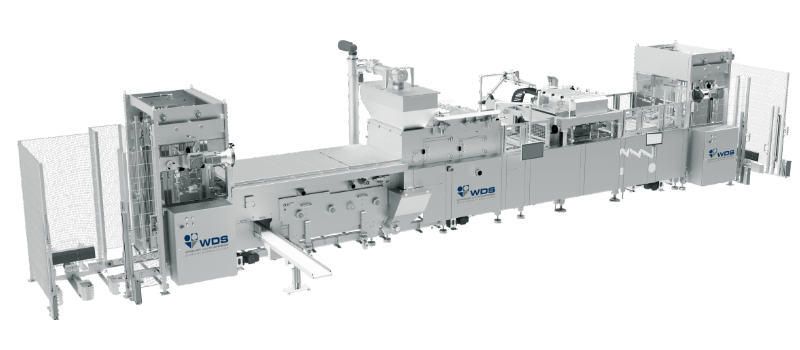

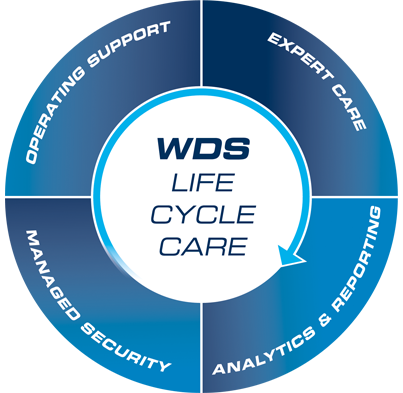

The WDS SmartMould presented at the Interpack 2017, a production mould equipped with sensor technology for recording process parameters, has been continuously developed further in recent years with regard to its handling.

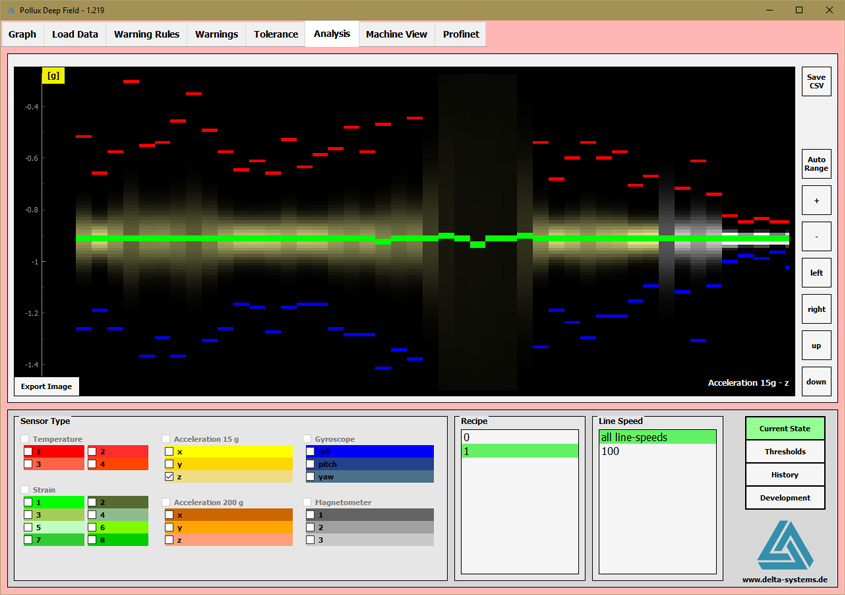

In the meantime, our SmartMould is able to detect and warn of unusual influences through Machine Learning, without the need to manually create a rule. These warnings can subsequently be manually classified to refine the analysis.

This facilitates the teach-in of the SmartMould enormously, as all limit values for each mould position are set automatically and this already after approx. 10 plant rotations.

The figure on the right shows the automatically set positive (red) and negative (blue) limits.

Deutsch

Deutsch  English

English  Русский

Русский